News

cutting-edge technology

In traditional shipbuilding workshops, plate beveling has long faced multiple operational challenges:

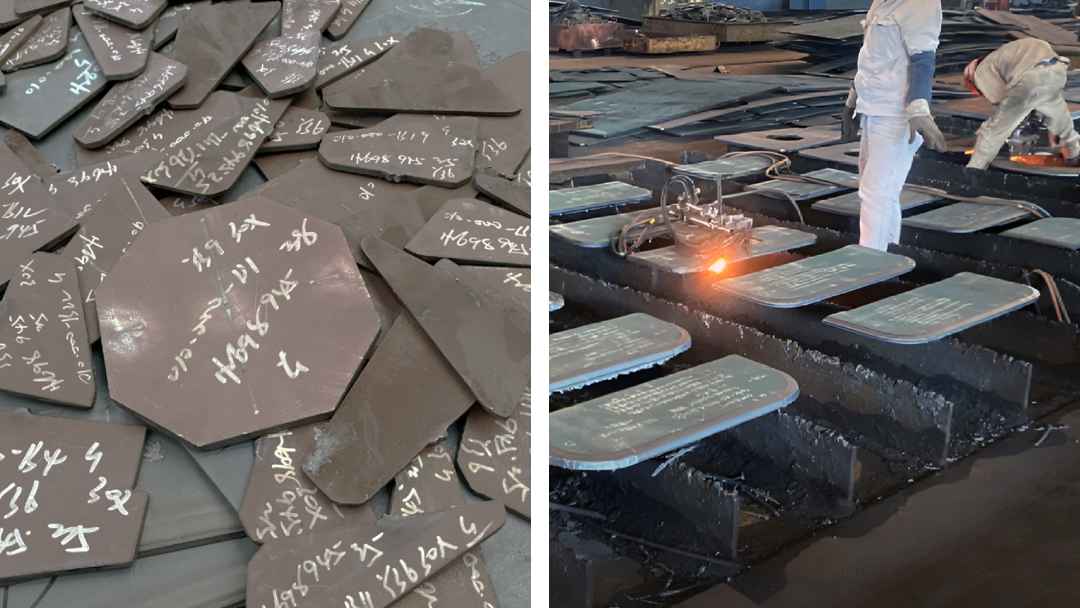

Extremely small batch sizes: sometimes only 1–2 pieces per workpiece, creating major flexibility demands.

Chaotic material flow: including secondary transfer of cut plates, mixed incoming materials, and disorganized stacking—requiring manual sorting and lowering efficiency.

Inconsistent material quality: negatively impacts bevel accuracy.

Fragmented workflows: lack of precise workpiece data and seamless information flow hinders intelligent transformation.

To address these issues, ROBOTICPLUS.AI developed the Intelligent Bevel Cutting System, overcoming the technical bottlenecks of small-batch, multi-variety, and disordered material stacking in shipbuilding plate processing. The system realizes a fully automated workflow—from intelligent sorting and loading to high-precision bevel cutting and smart discharge with panel matching.

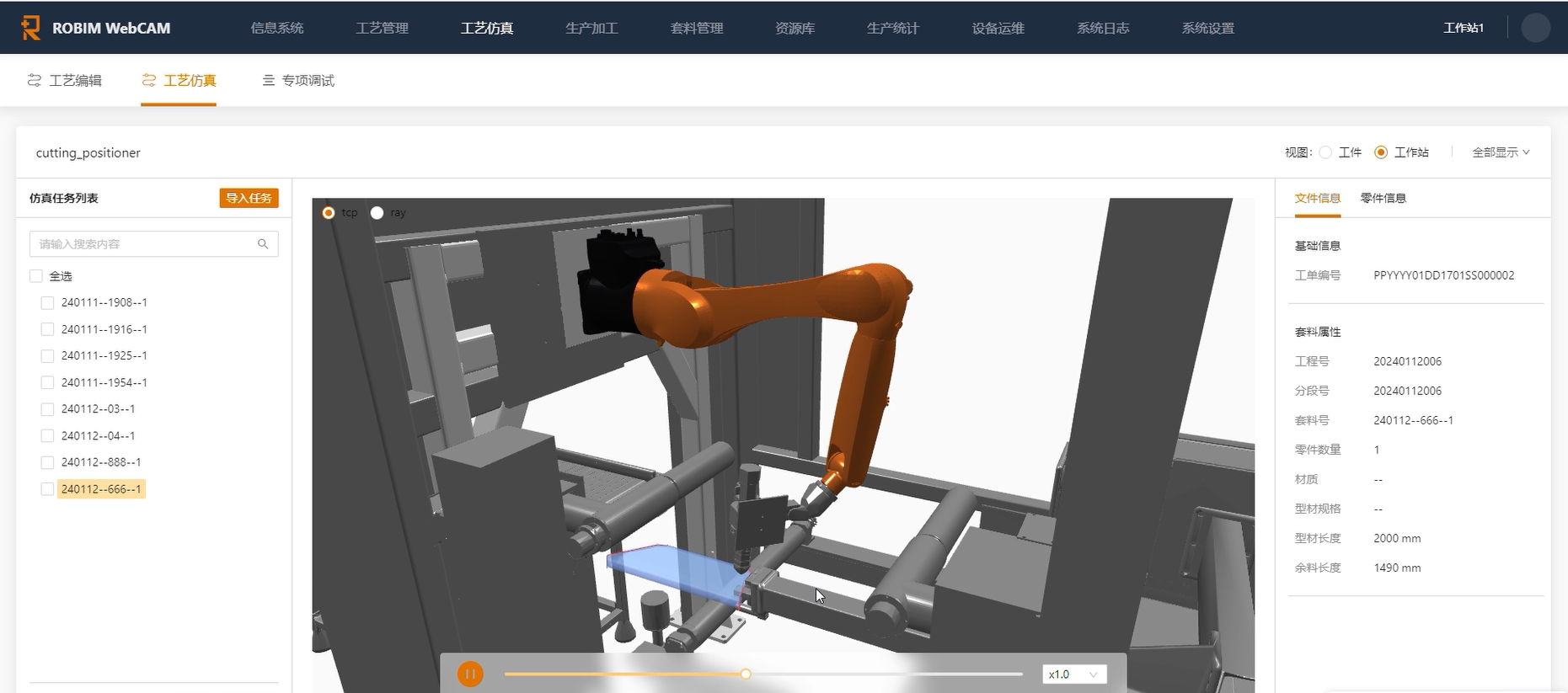

Powered by the RobimCut software, the system automatically reads LST data exported from SPD, rapidly generating 3D models with bevel information. This enables seamless integration from design to production and fully automated planning.

Using AI deep learning OCR technology, the system accurately identifies part numbers on plates even when misaligned or angled, achieving a recognition accuracy ≥95%. It completely eliminates manual verification and production scheduling steps.

By combining high-precision point cloud scanning with AI algorithms, the system clearly identifies chaotically stacked plates, precisely determining each plate’s position and shape to guide automated loading and unloading.

Fully integrated with factory management systems, the intelligent dashboard provides real-time visibility of equipment status, production output, and energy consumption—supporting data-driven decision-making and efficient operations.

Operational results show that the system can process 30–60 parts per hour. Under a two-shift model, it can replace the workload of 6–8 operators—significantly improving productivity and optimizing manpower allocation.

By enhancing efficiency, precision, and digital connectivity, ROBOTICPLUS.AI’s Intelligent Bevel Cutting System has set a new automation benchmark in shipbuilding plate processing—offering a scalable, replicable pathway toward intelligent manufacturing transformation in the industry.