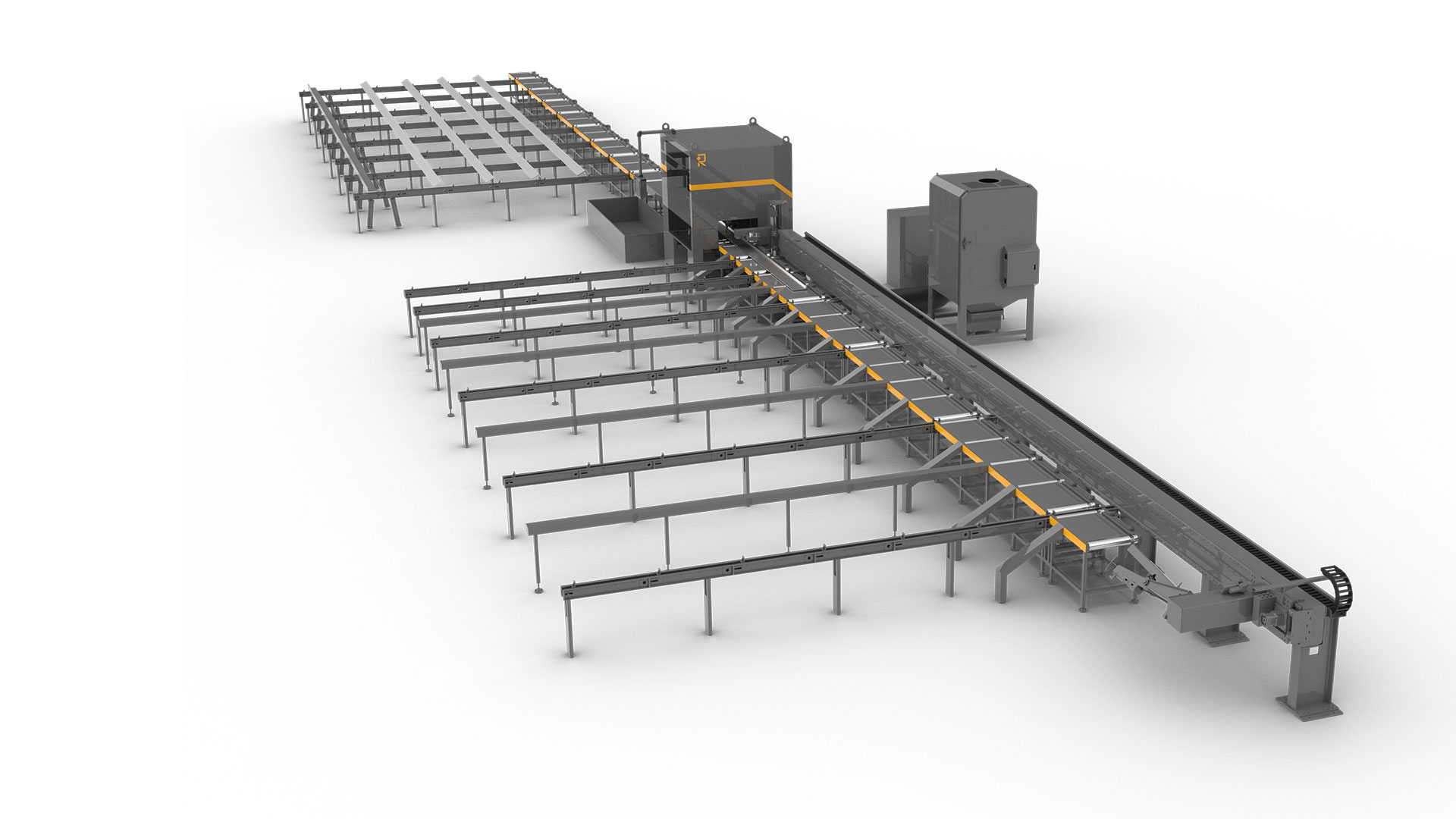

RobimCutProfile system is developed to meet the cutting needs of shipbuilding, offshore engineering, construction, and other industries. Built around the core RoBIM industrial software, it combines high-precision hardware with deep expertise in cutting processes. The system supports a wide variety of profile types and enables fully automated control of the entire cutting workflow.

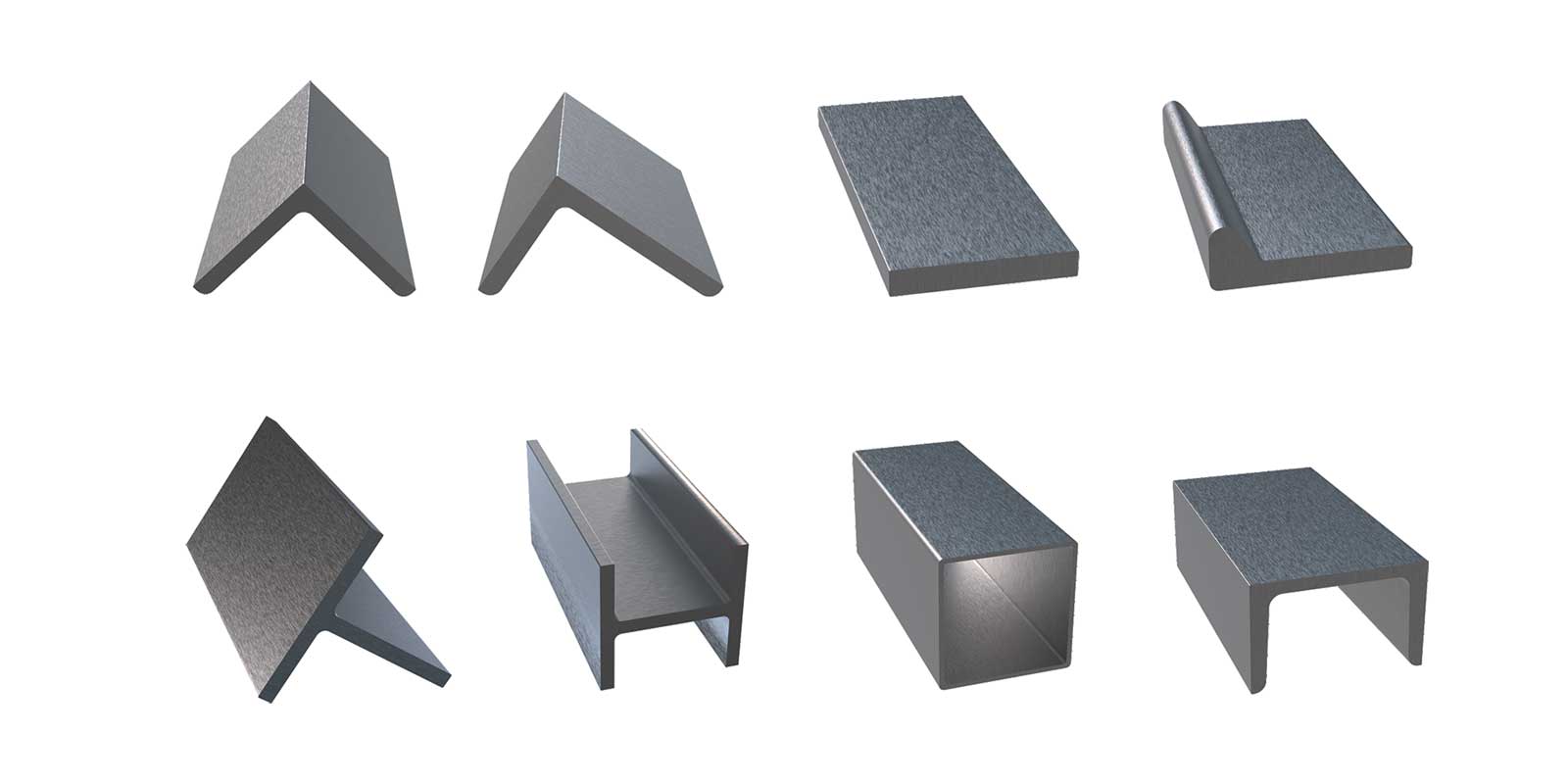

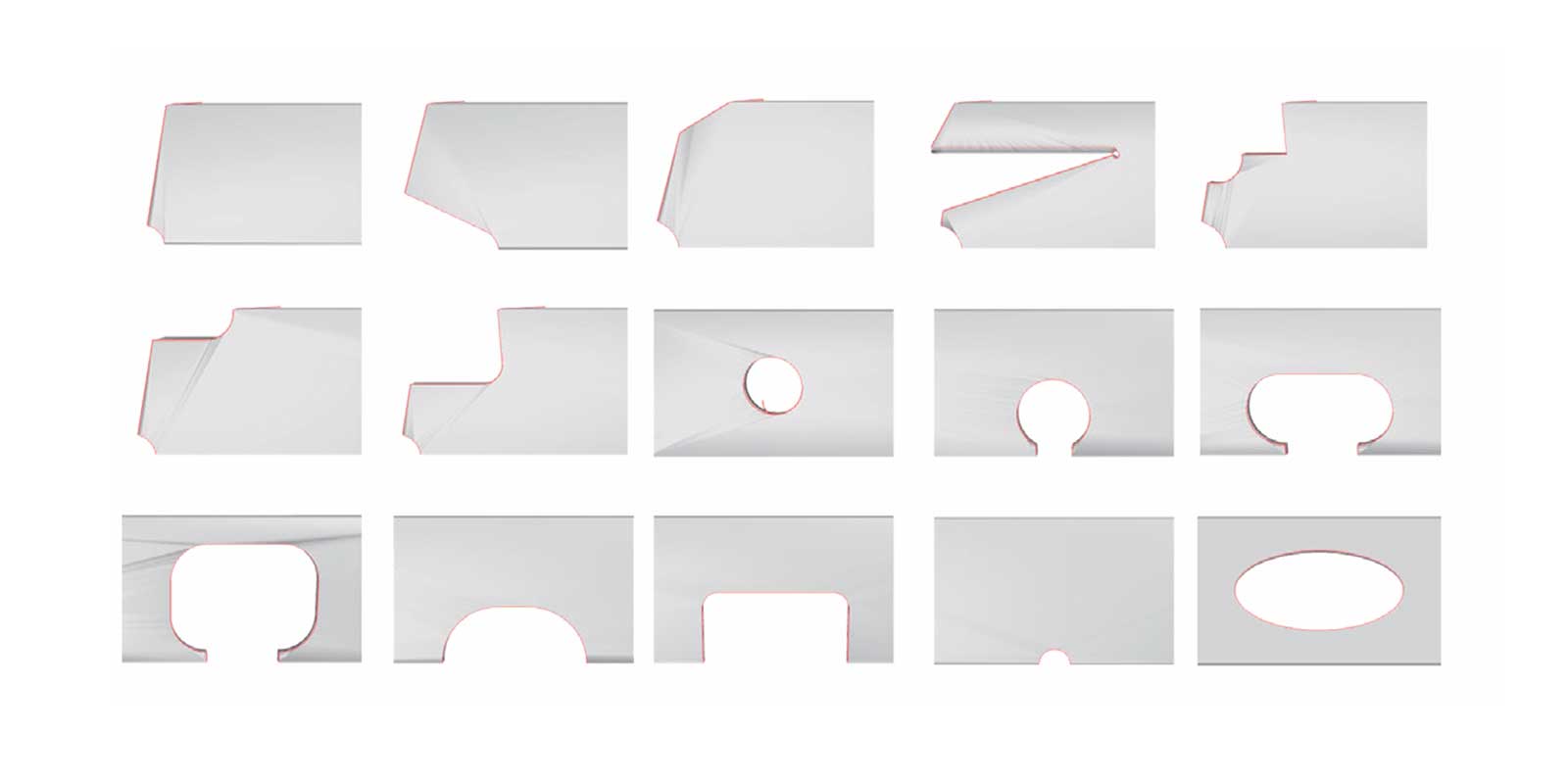

Handle everything from equal and unequal angle steel to flat bars, ball flat steel, T-beams, H-beams, and channel steel — all with a single versatile machine designed for maximum flexibility.

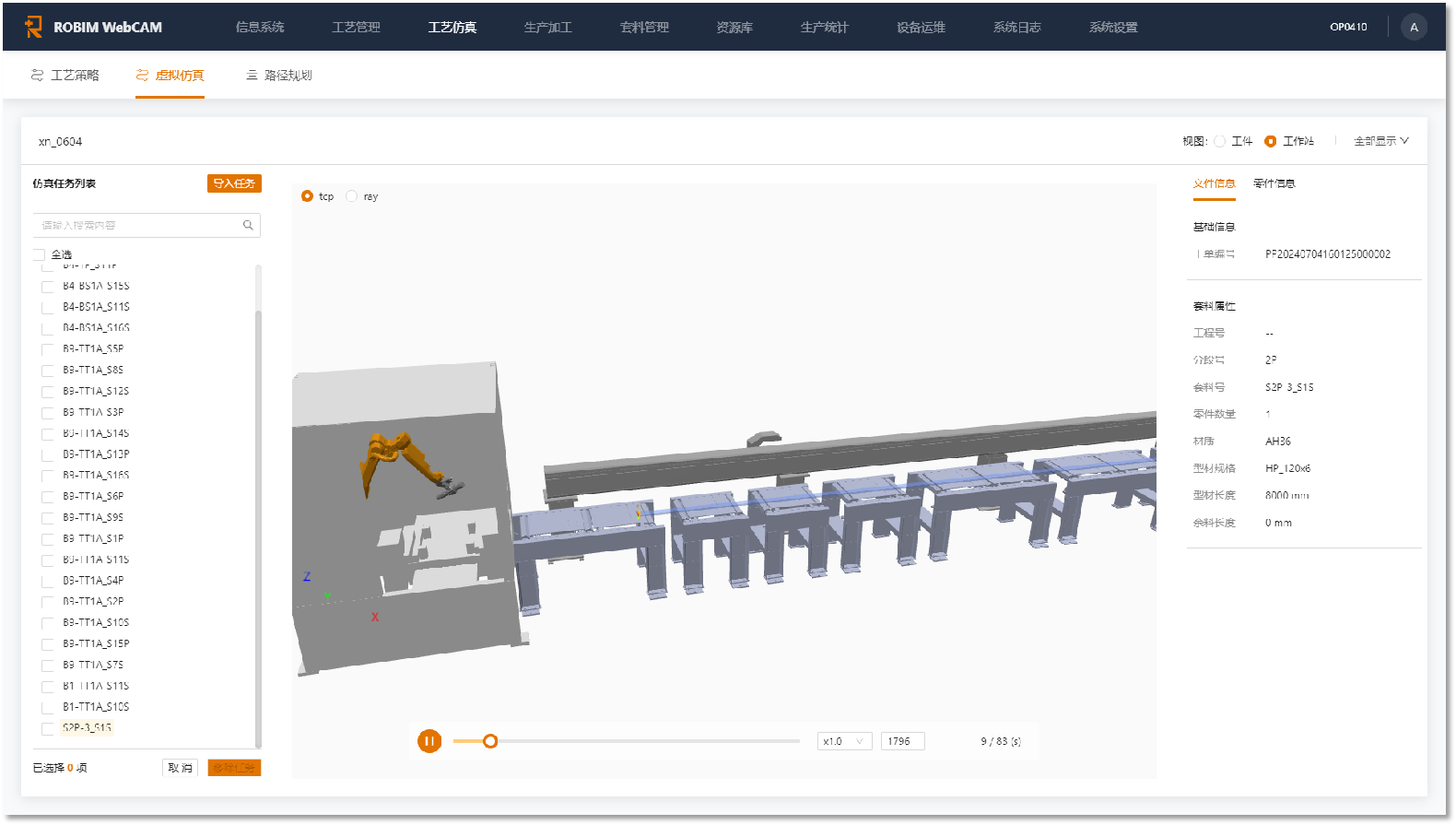

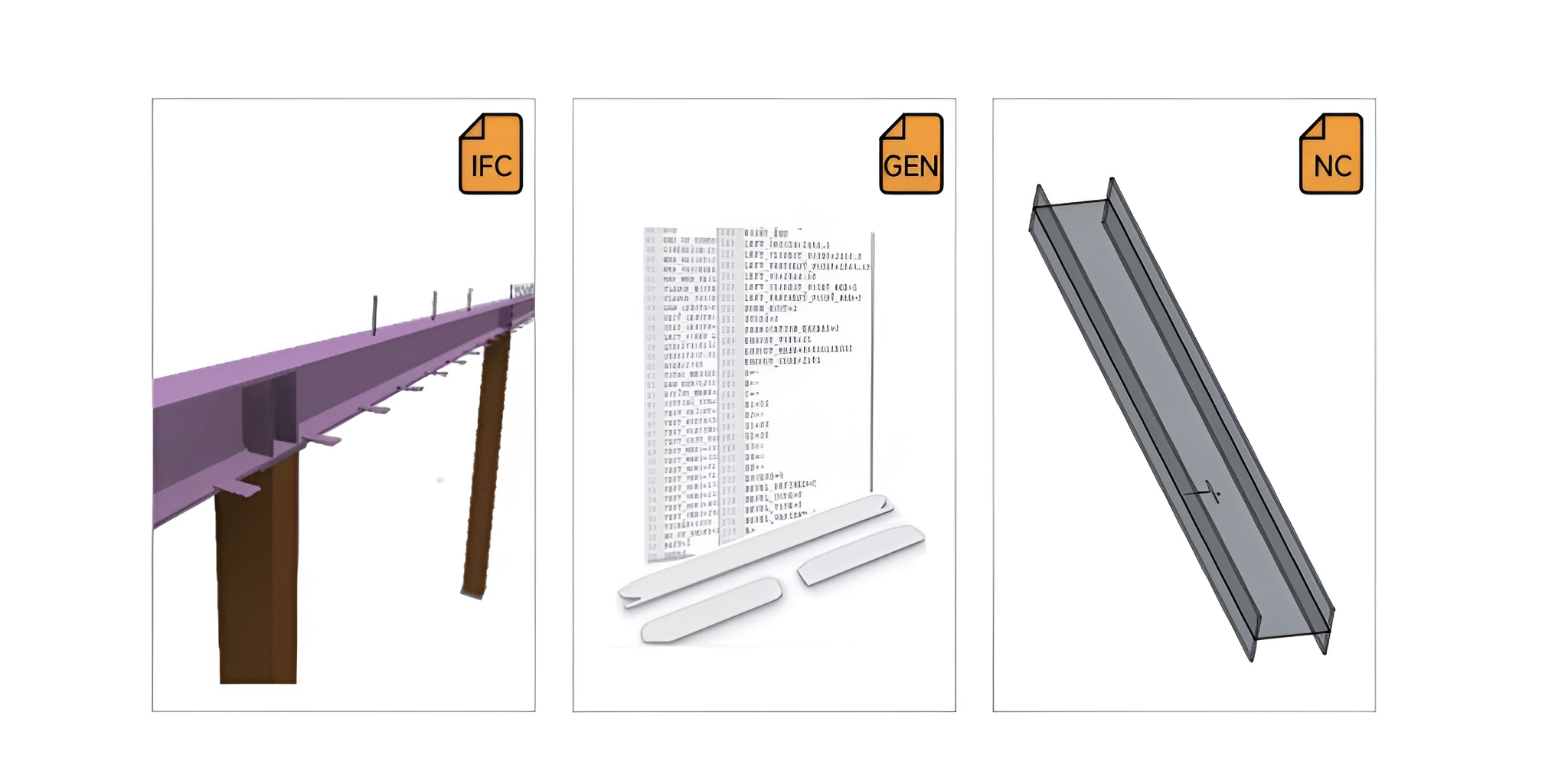

Compatible with design software such as Tribon, AVEVA, CATIA, SPD, TEKLA, and CAD.— stream lining your workflow from design to cutting.

Access over 100 predefined macro shapes, with the freedom to customize through secondary development — giving you unmatched adaptability for any project.

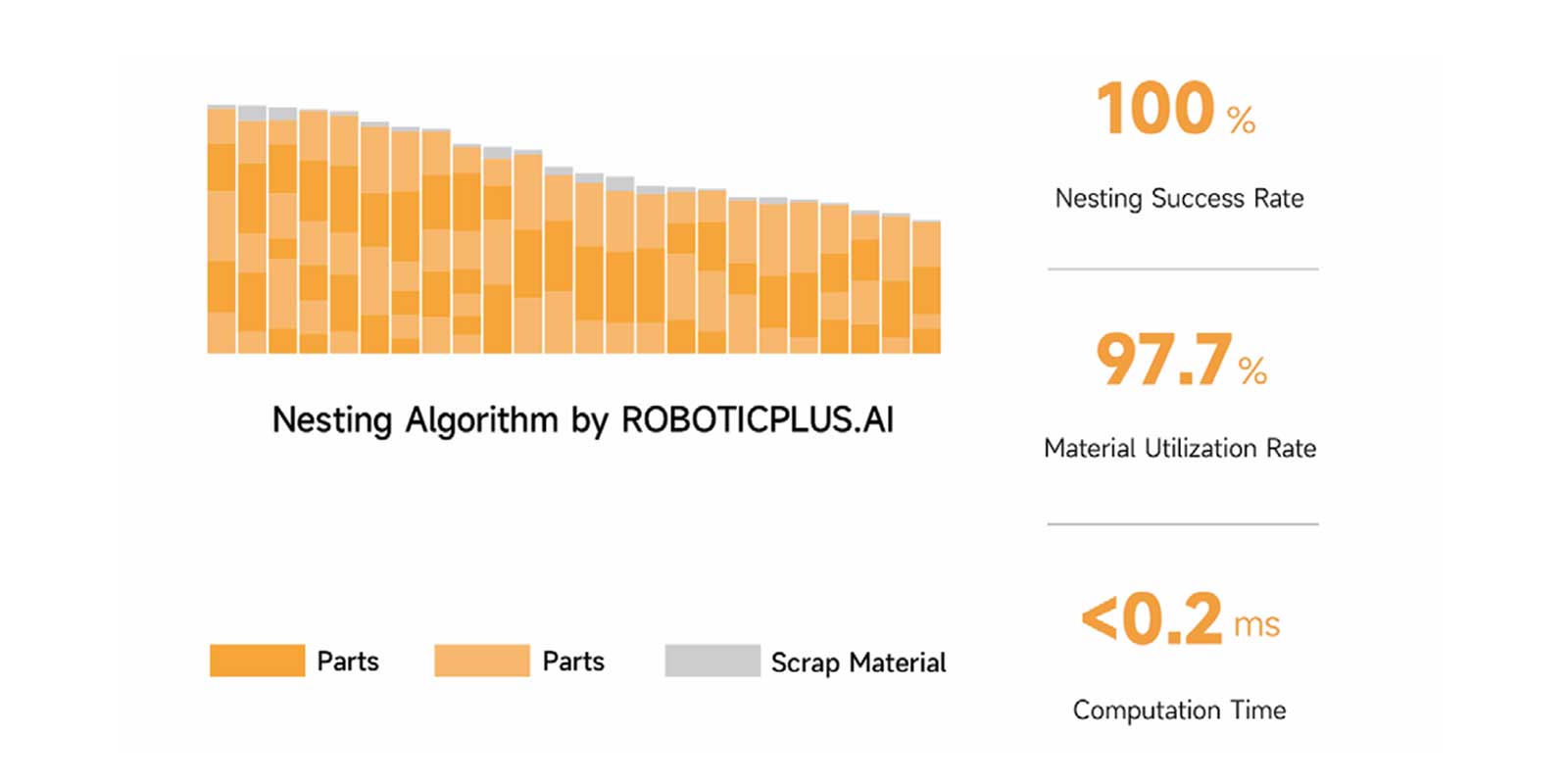

Our cutting-edge nesting algorithms optimize material usage, dramatically reducing waste and saving you money on every job.

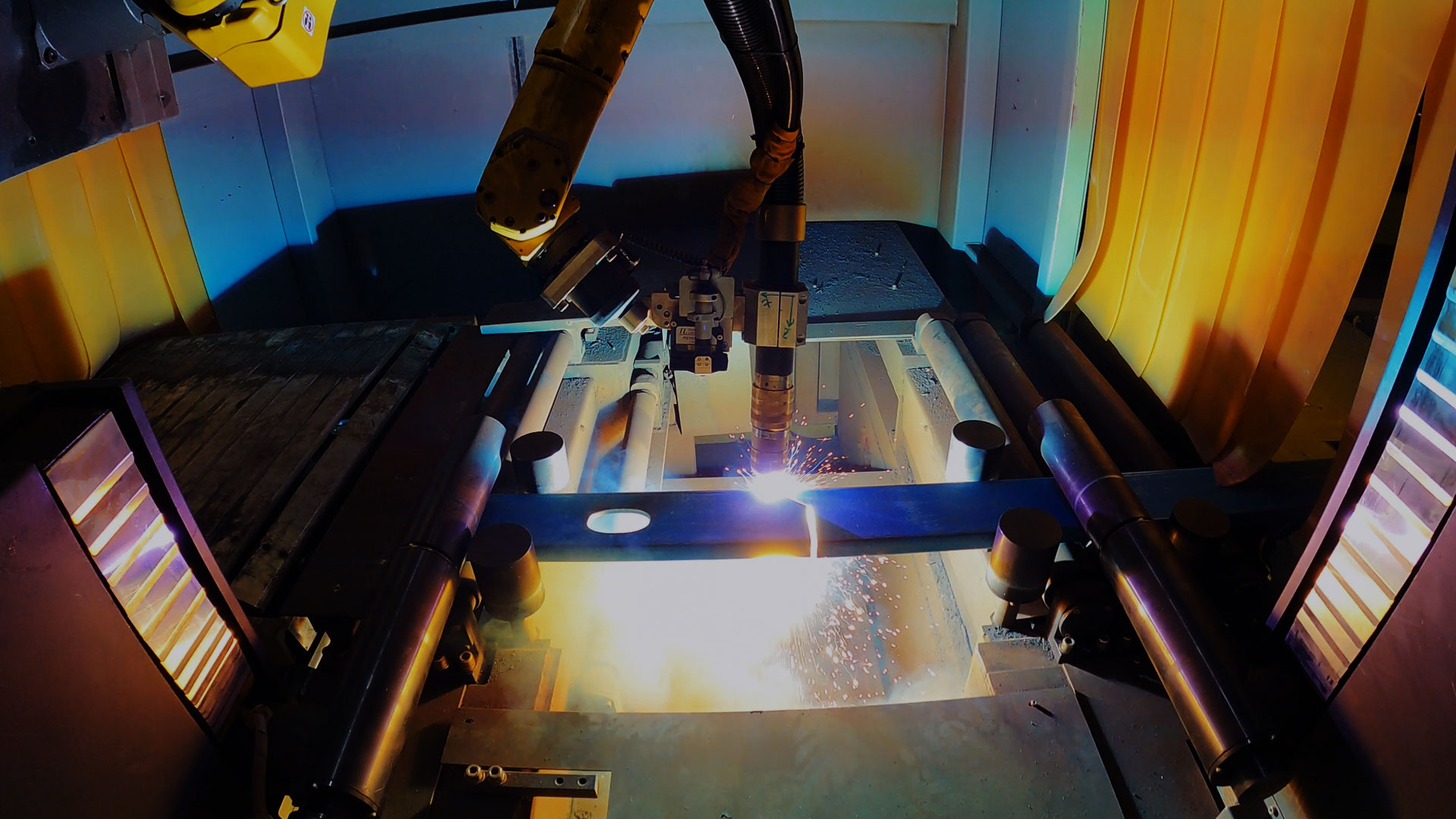

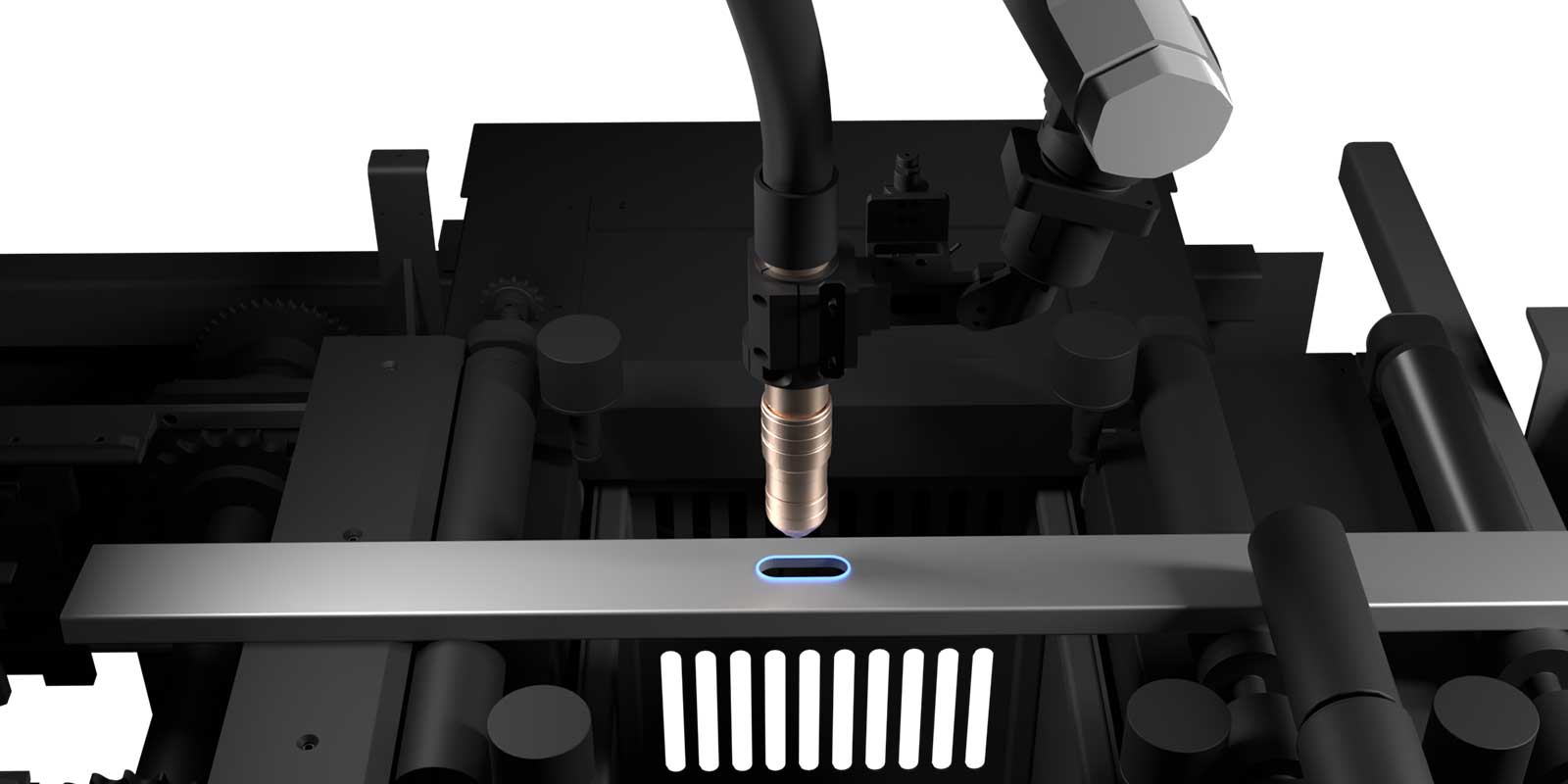

The robot not only cuts — it thinks. It senses obstacles and adjusts its path in real time, delivering precise and efficient cuts with minimal supervision.

Thanks to a comprehensive cutting parameter database, the system continually adjusts during cutting to deliver consistent, top-quality results every time.