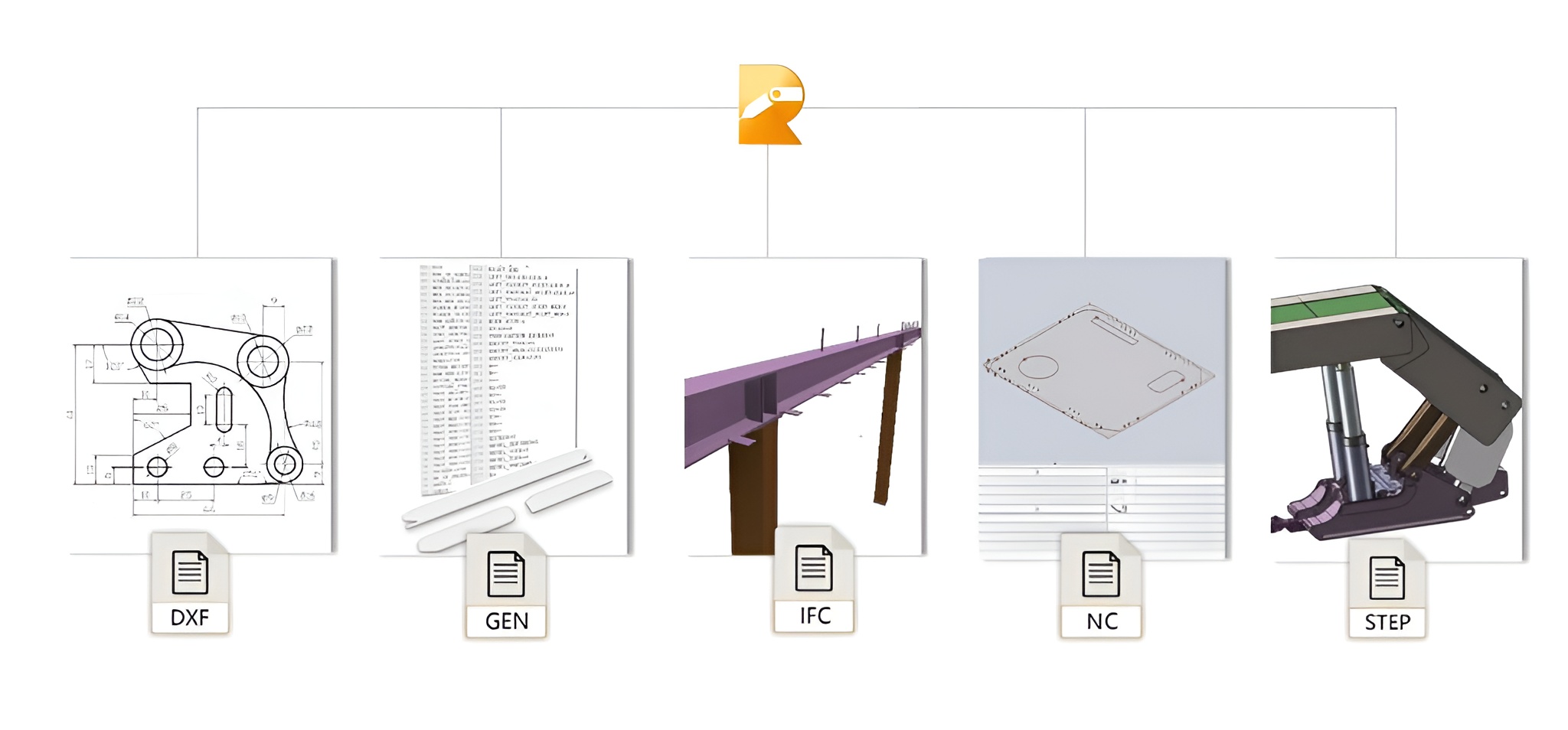

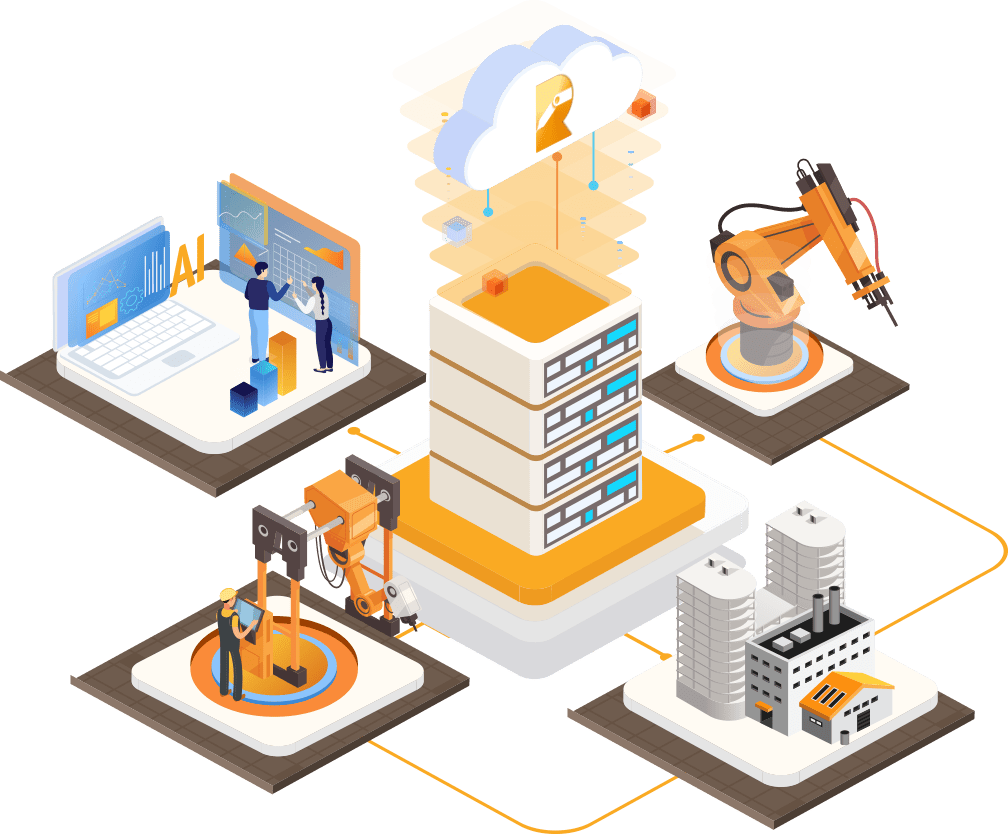

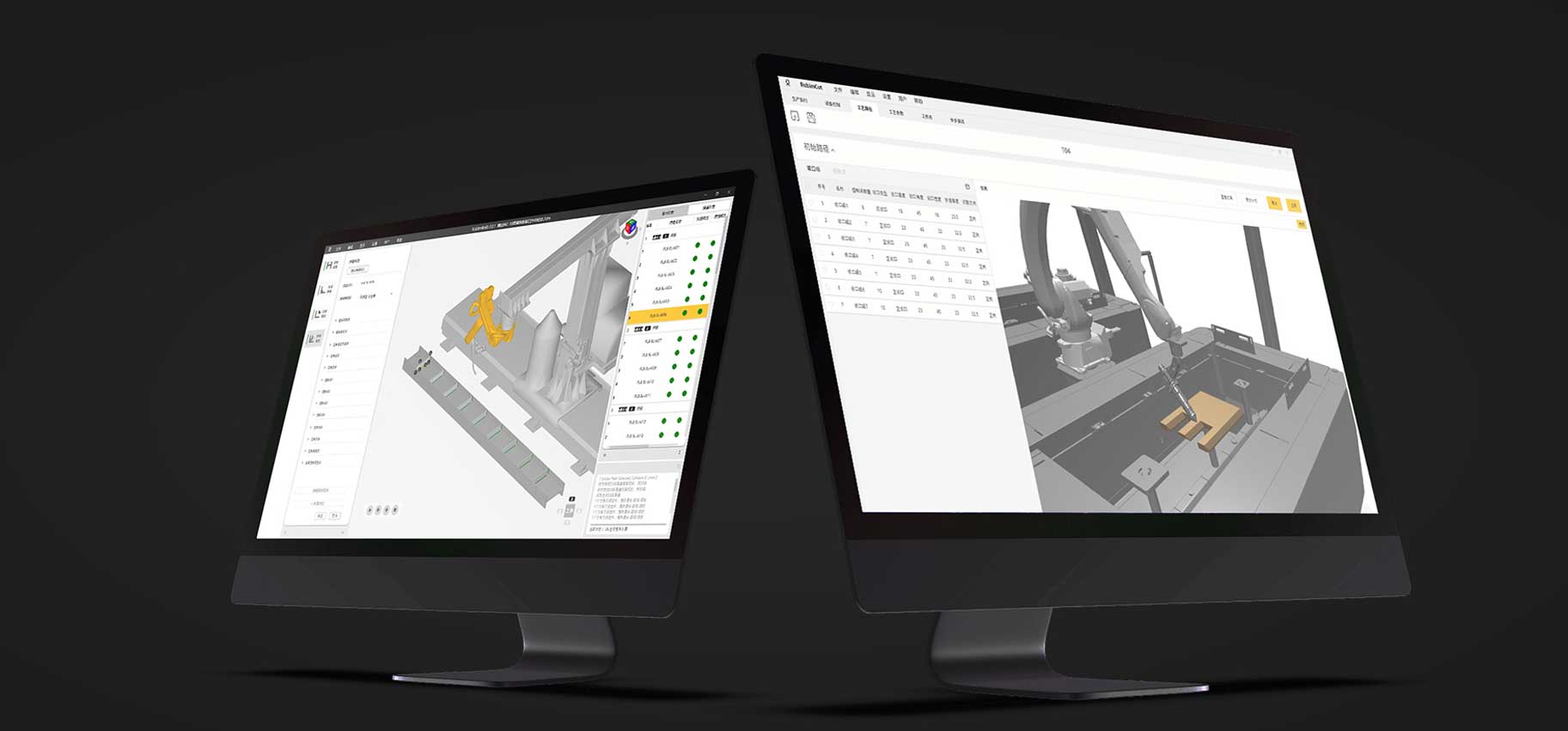

RoBIM — Flexible Robotic Control Platform

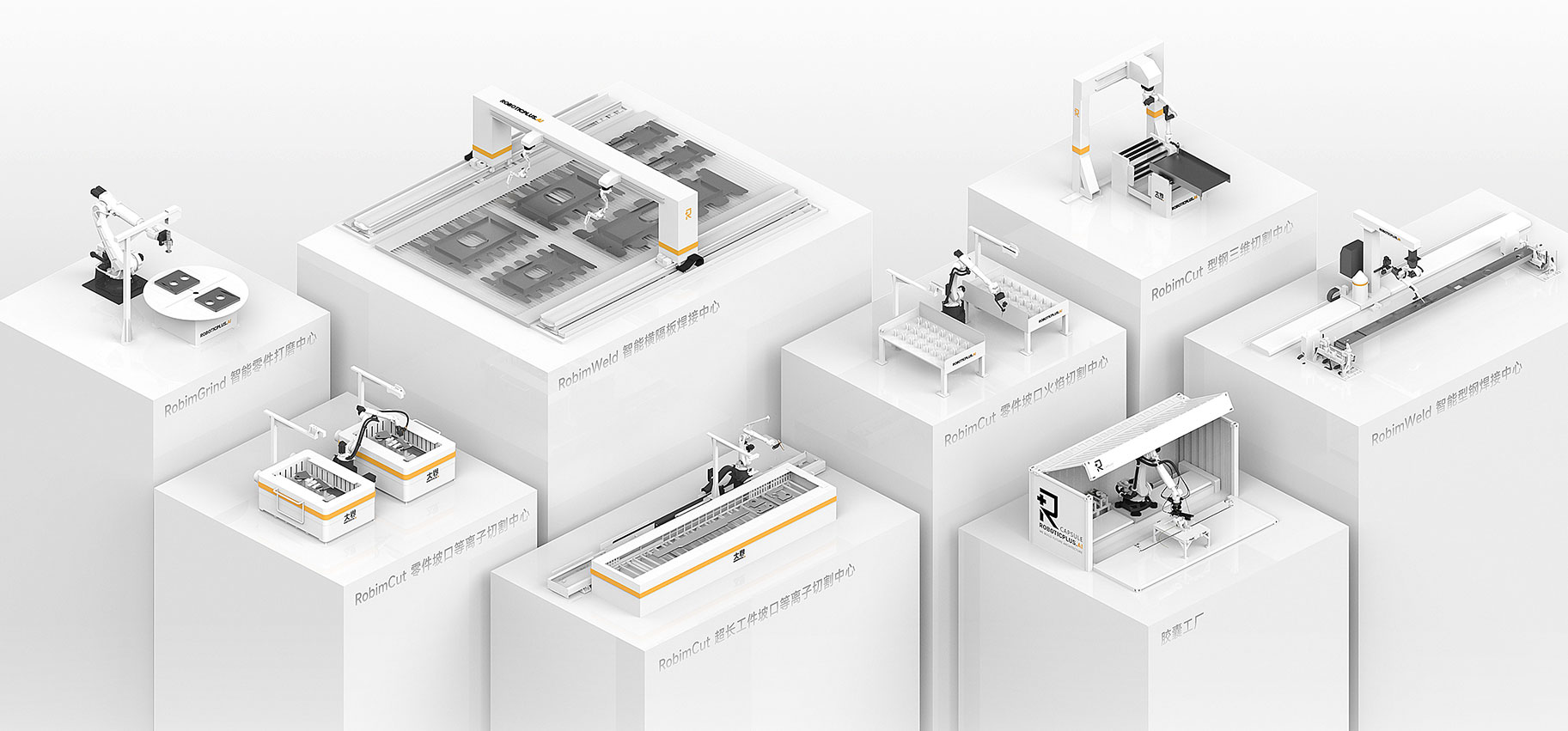

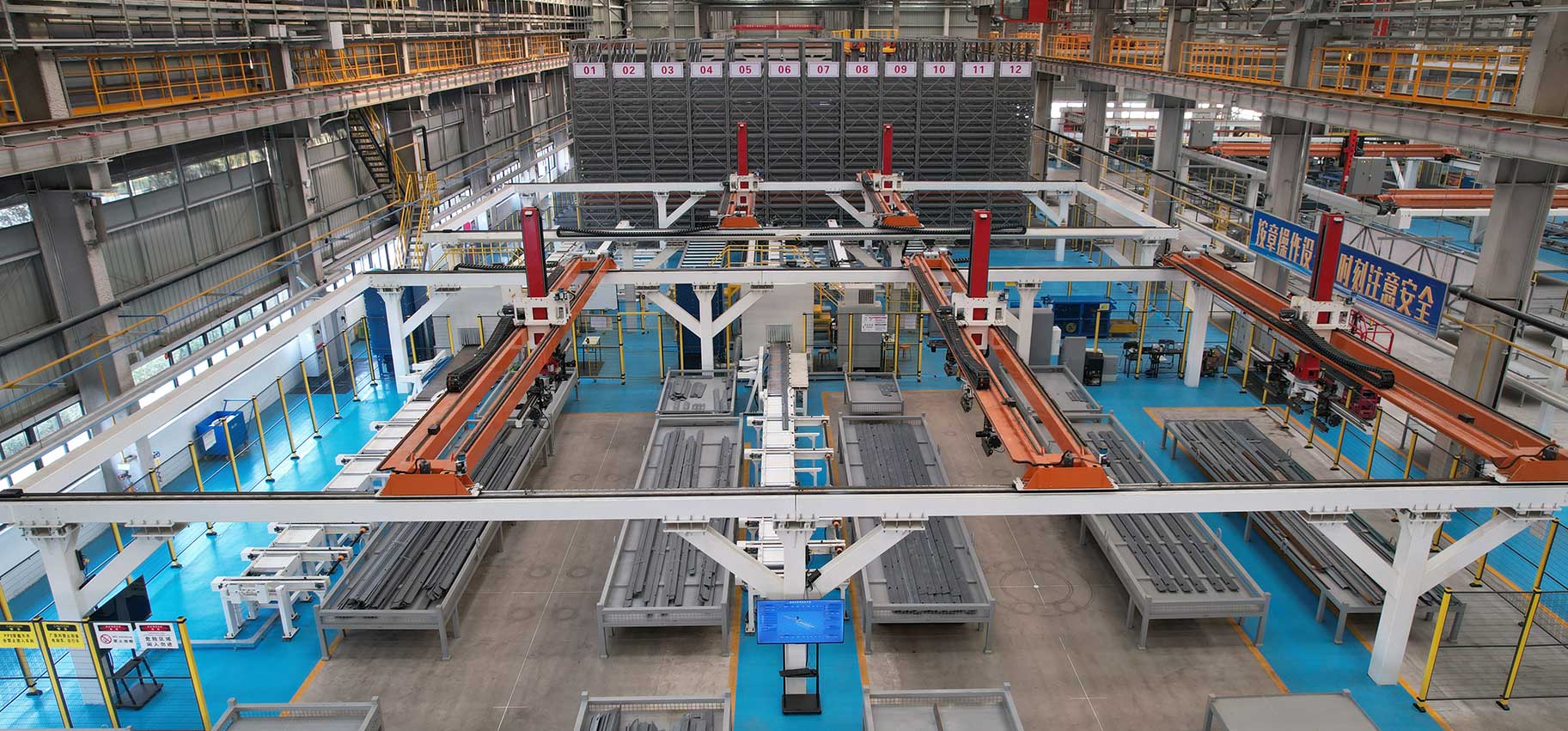

RoBIM is a flexible control software platform for industrial robots based on CAD–CAPP–CAM data flow. With CAPP technology as the core, it drives flexible production of robots through feature modeling and process adaptation.