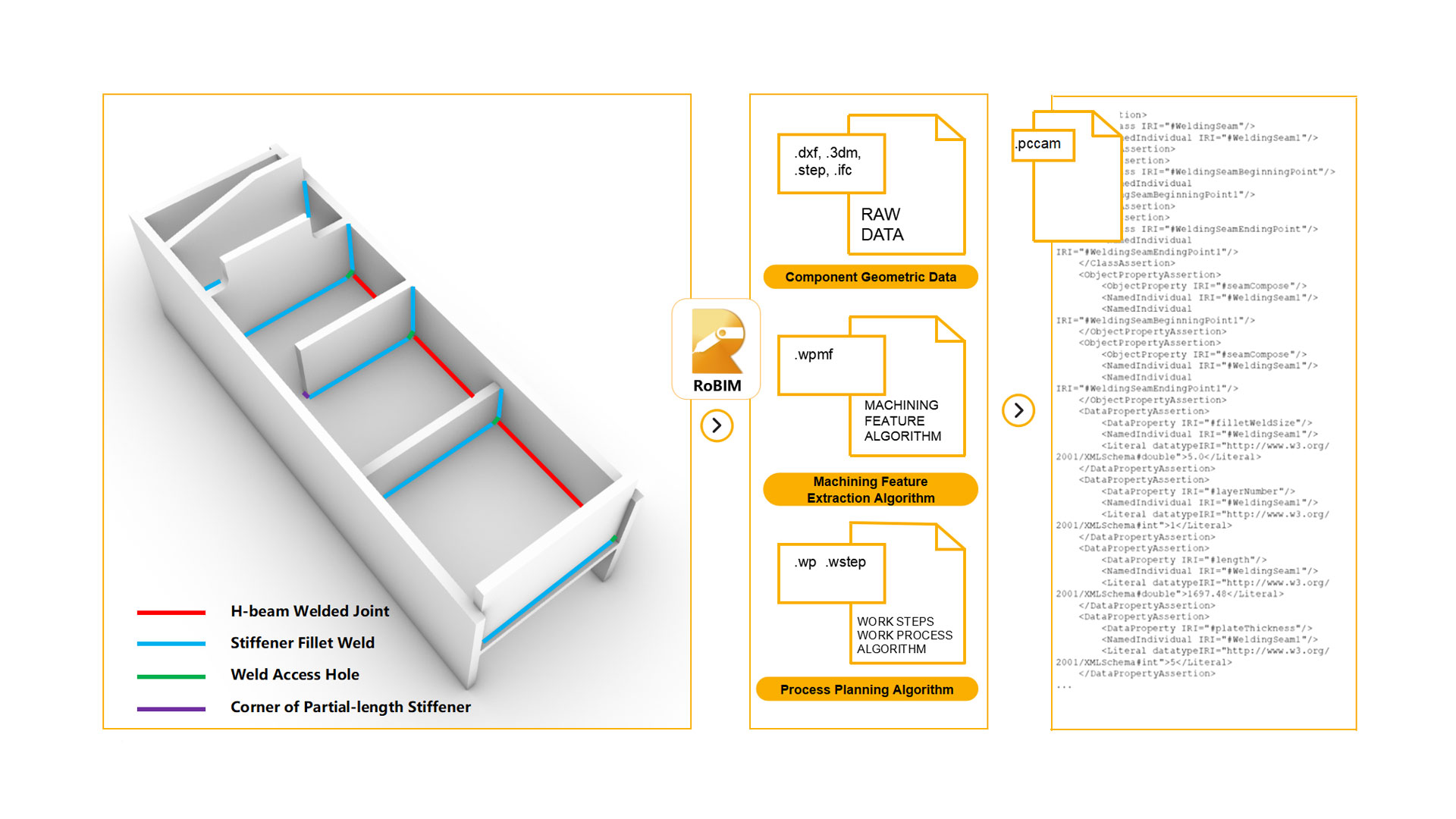

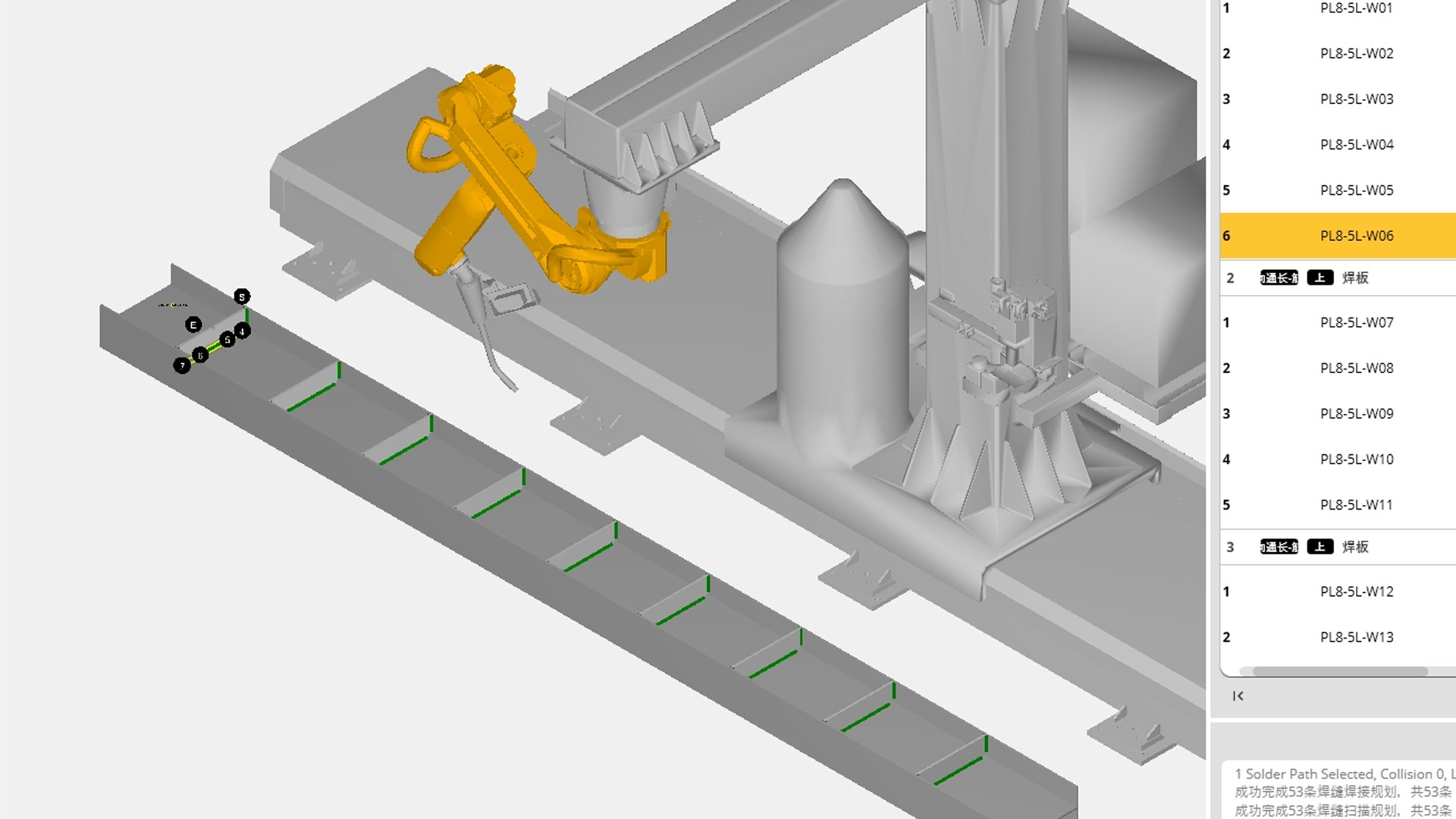

RobimWeld effortlessly connects with upstream CAD design software, rapidly importing raw data from IFC, DXF, STL, STP, and other key file formats. It then intelligently generates precise weld seam layouts, welding procedures, and optimized robot welding paths—streamlining your workflow and boosting production efficiency.

Requires no additional configuration for the design model and seamlessly integrates with mainstream steel structure detailing software. Eliminates the need for component drawings and related drafting steps, substantially reducing process labeling time.

Automatically calculates fillet weld sizes.

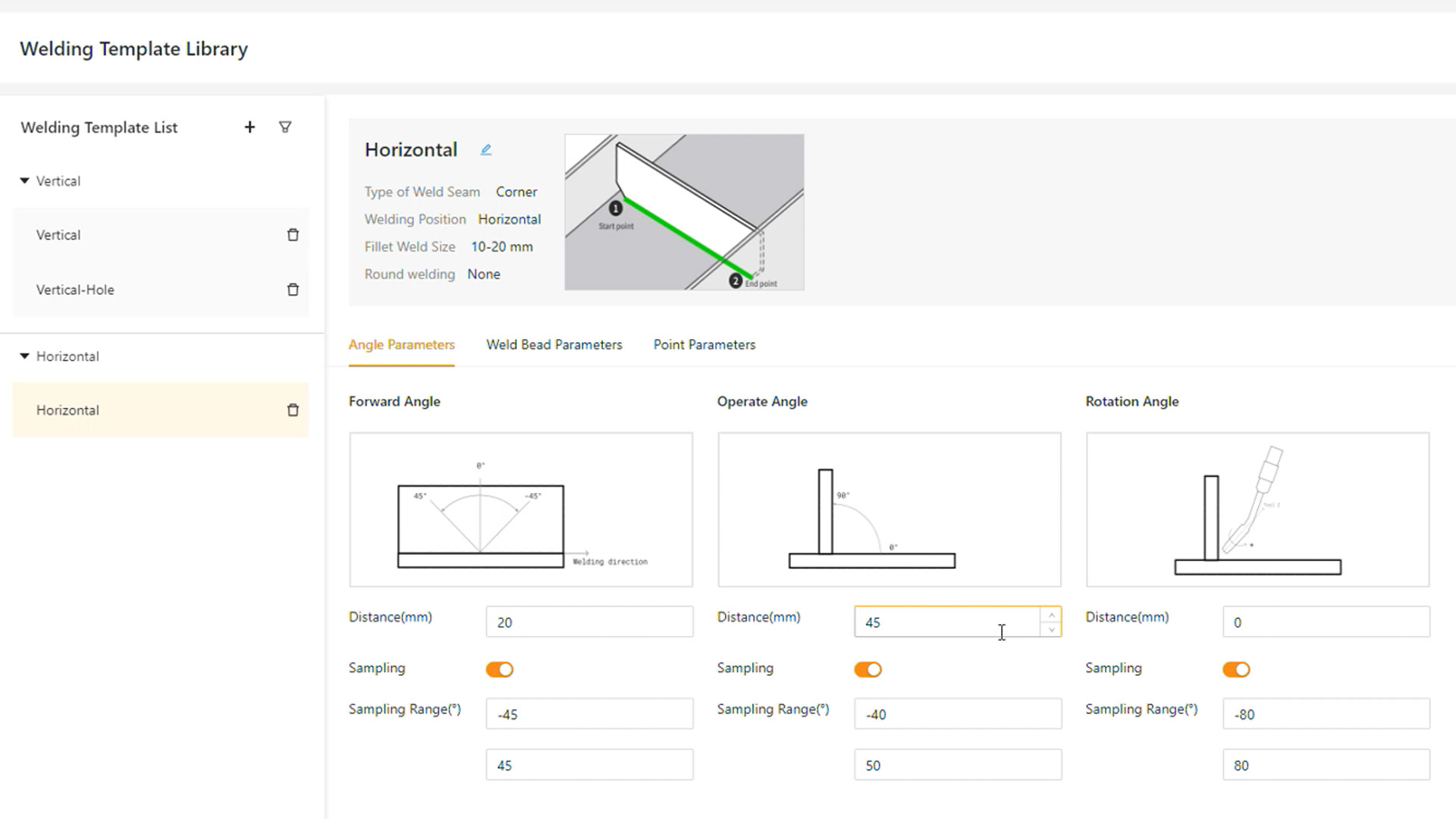

Flexible, rule-based welding configurations.

Auto-matching optimal welding parameters.

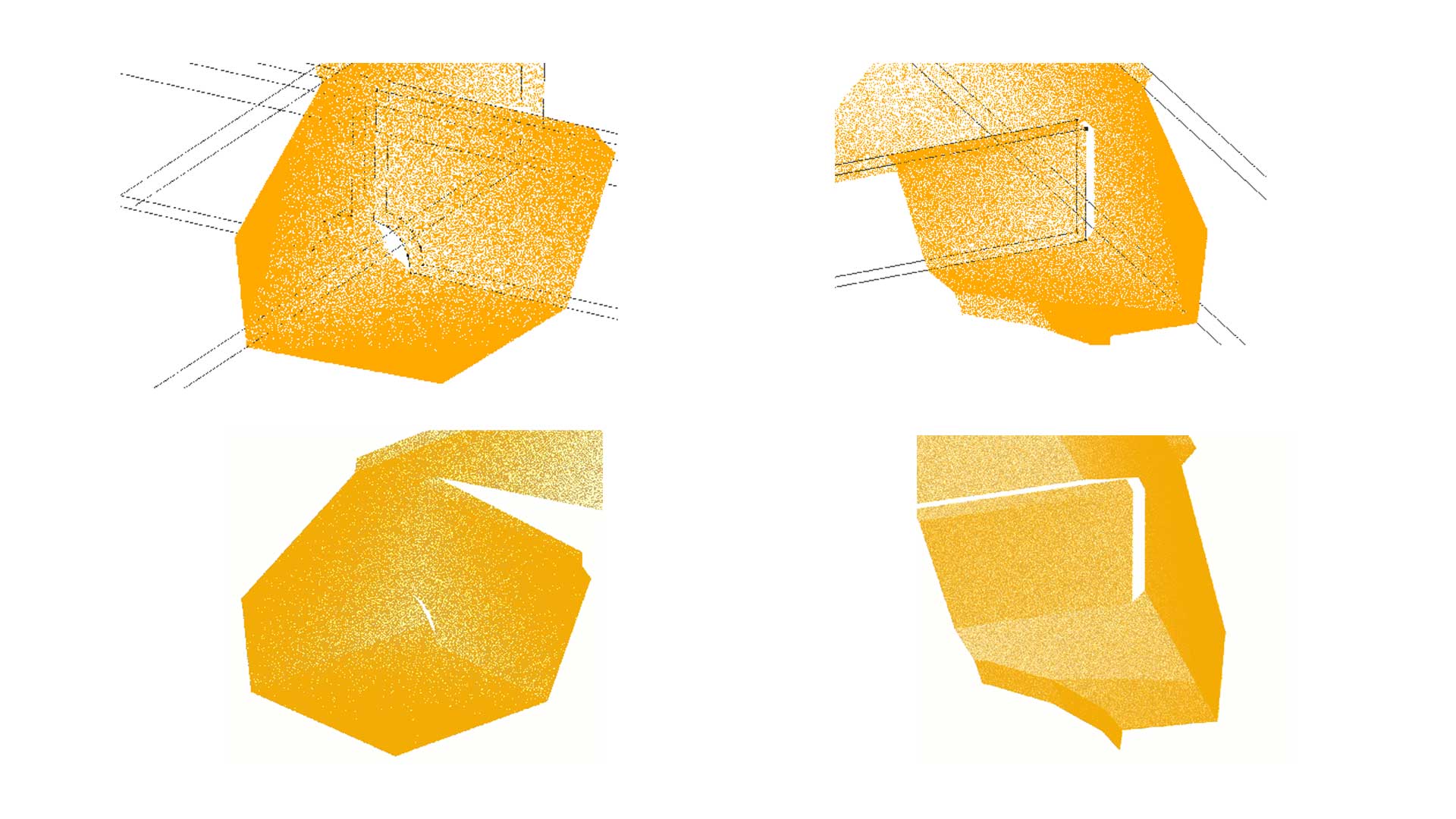

Auto-generates weld seams from model geometrys.

Automatically calculates torch angles and robot paths.

Supports advanced manual customization when needed.

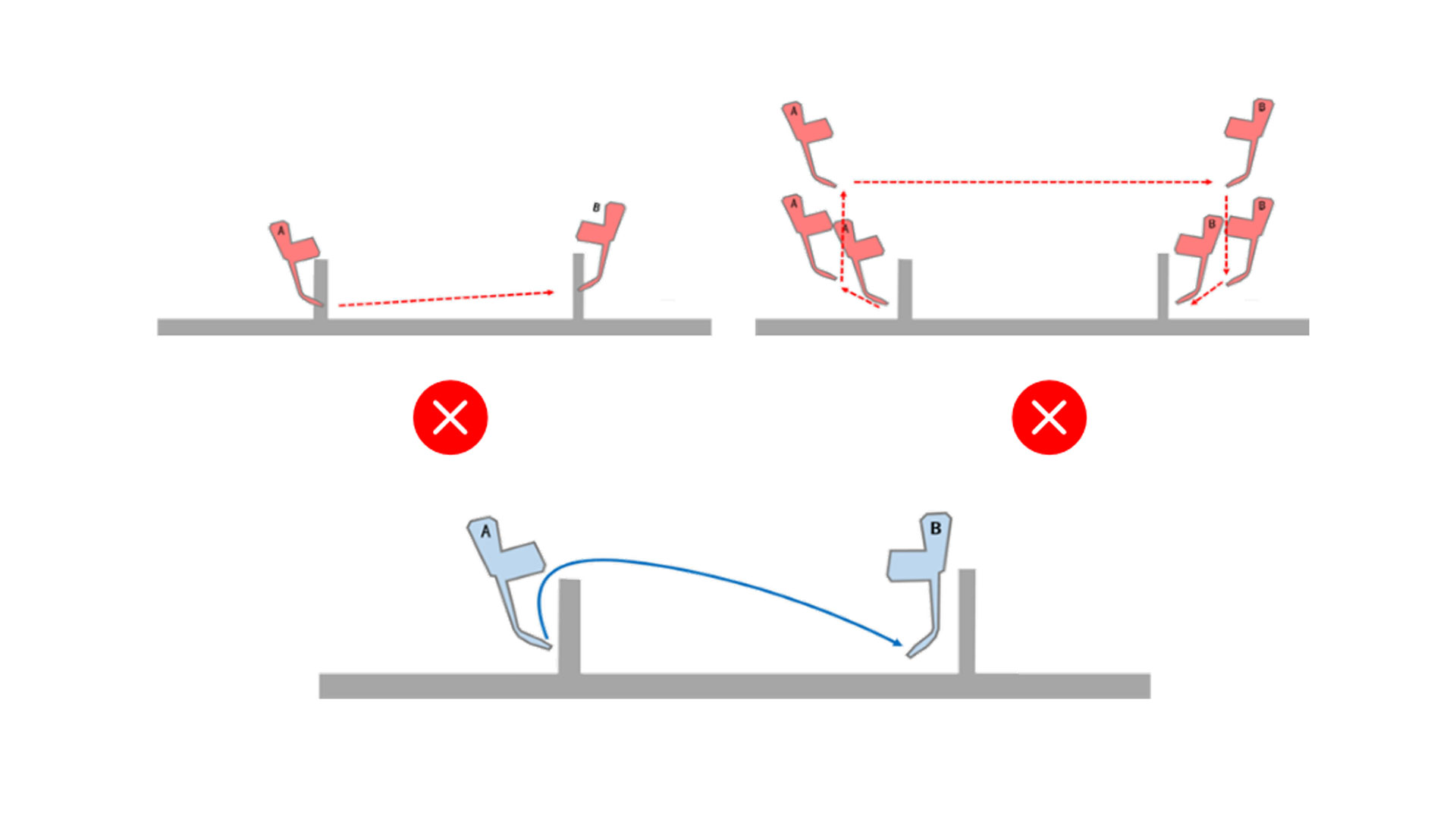

Reliable, built-in collision avoidance.

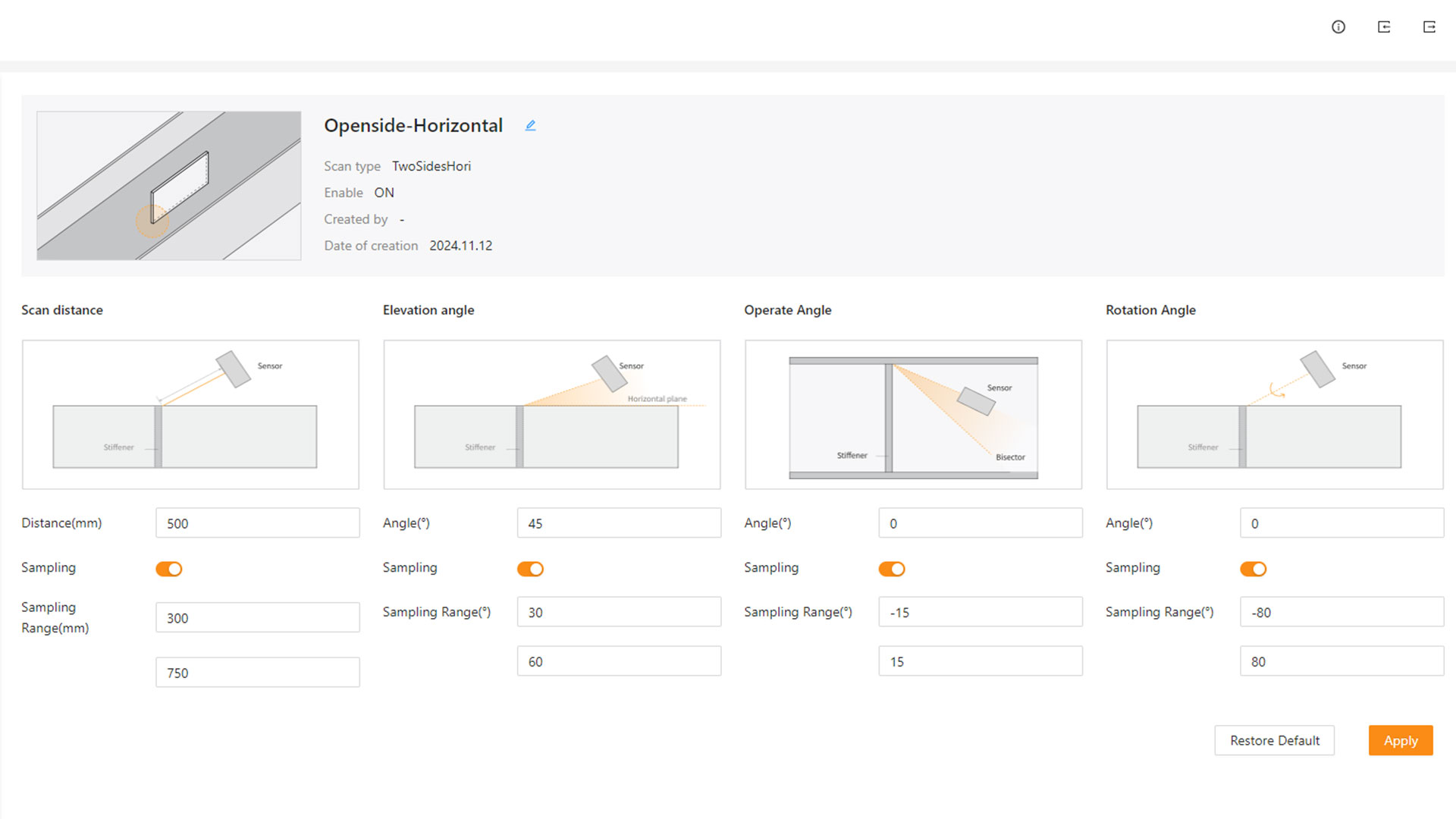

Adaptive positioning for complex joint geometries.

Optimizes weld paths for better efficiency and results.

Auto-recognizes and classifies parts from the model.

Adaptive positioning for complex joint geometries.

Automatically detects plate thicknesses and dimensions.

Automatic interference and collision detection.

Full-process robotic welding simulation with visual feedback.