Automated oxy-fuel and plasma bevel cutting for architectural steel, shipbuilding, and heavy industry. Powered by RoBIM software—no programming or teaching needed.

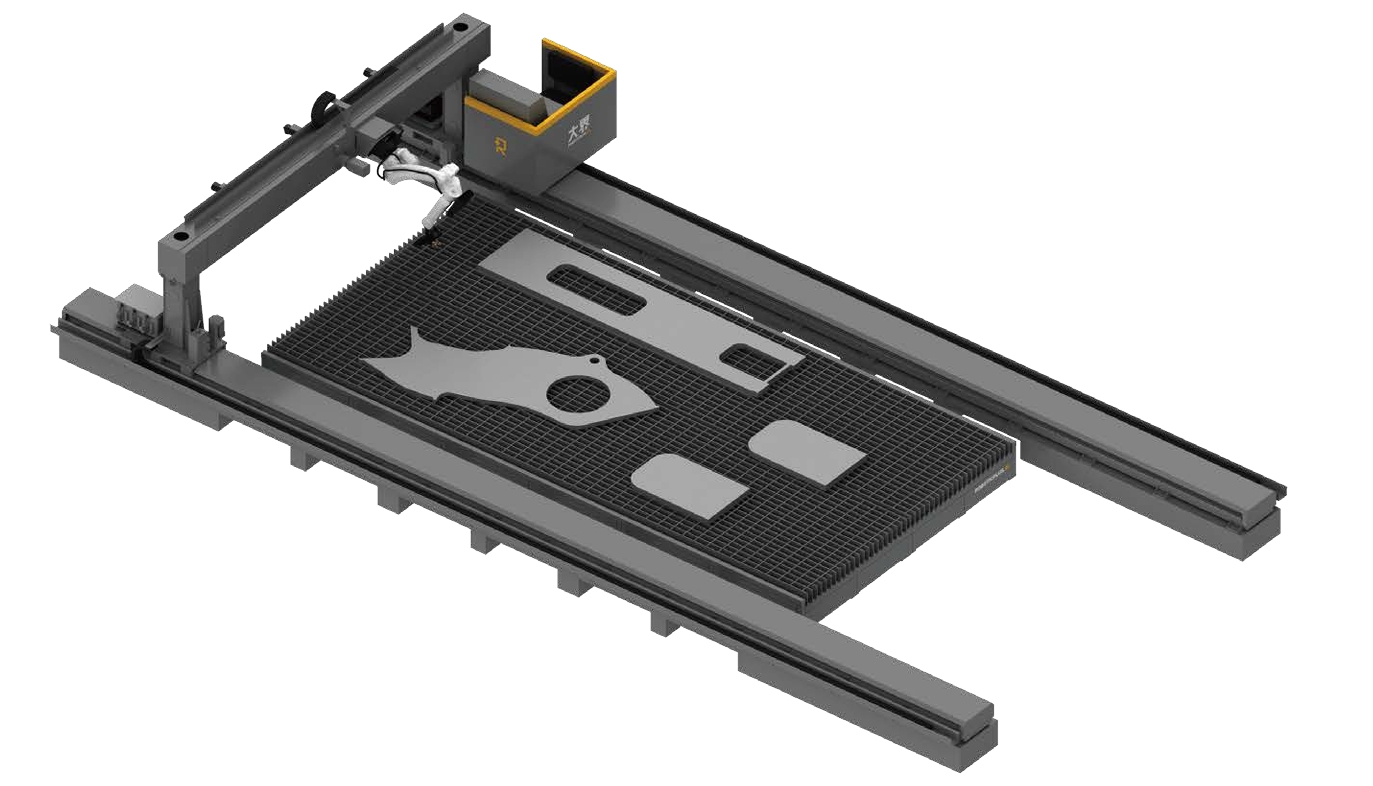

![]() A single tooling table supports multiple parts with arbitrary placement—no need for fixed positioning.

A single tooling table supports multiple parts with arbitrary placement—no need for fixed positioning.

![]() The 3D camera takes one picture to quickly and accurately find the workpiece’s position and shape, ensuring a high-quality cut.

The 3D camera takes one picture to quickly and accurately find the workpiece’s position and shape, ensuring a high-quality cut.

![]() Intuitive system design allows one operator to manage multiple machines with ease.

Intuitive system design allows one operator to manage multiple machines with ease.

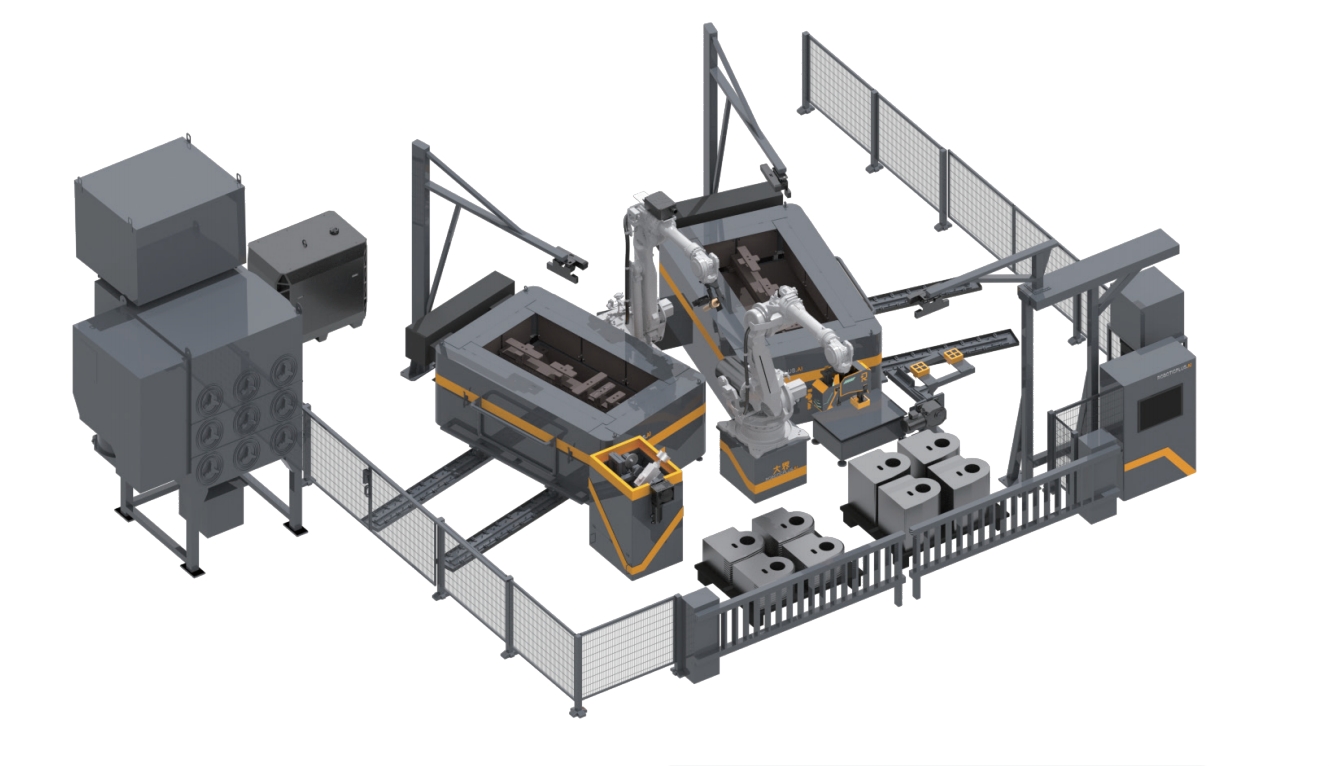

![]() Automated loading and unloading guided by 3D vision.

Automated loading and unloading guided by 3D vision.

![]() High-precision visual positioning for accurate alignment.

High-precision visual positioning for accurate alignment.

![]() Integrated grinding function—no need for manual post-processing.

Integrated grinding function—no need for manual post-processing.

![]() Supports processing of medium-thickness plates (8–45 mm).

Supports processing of medium-thickness plates (8–45 mm).

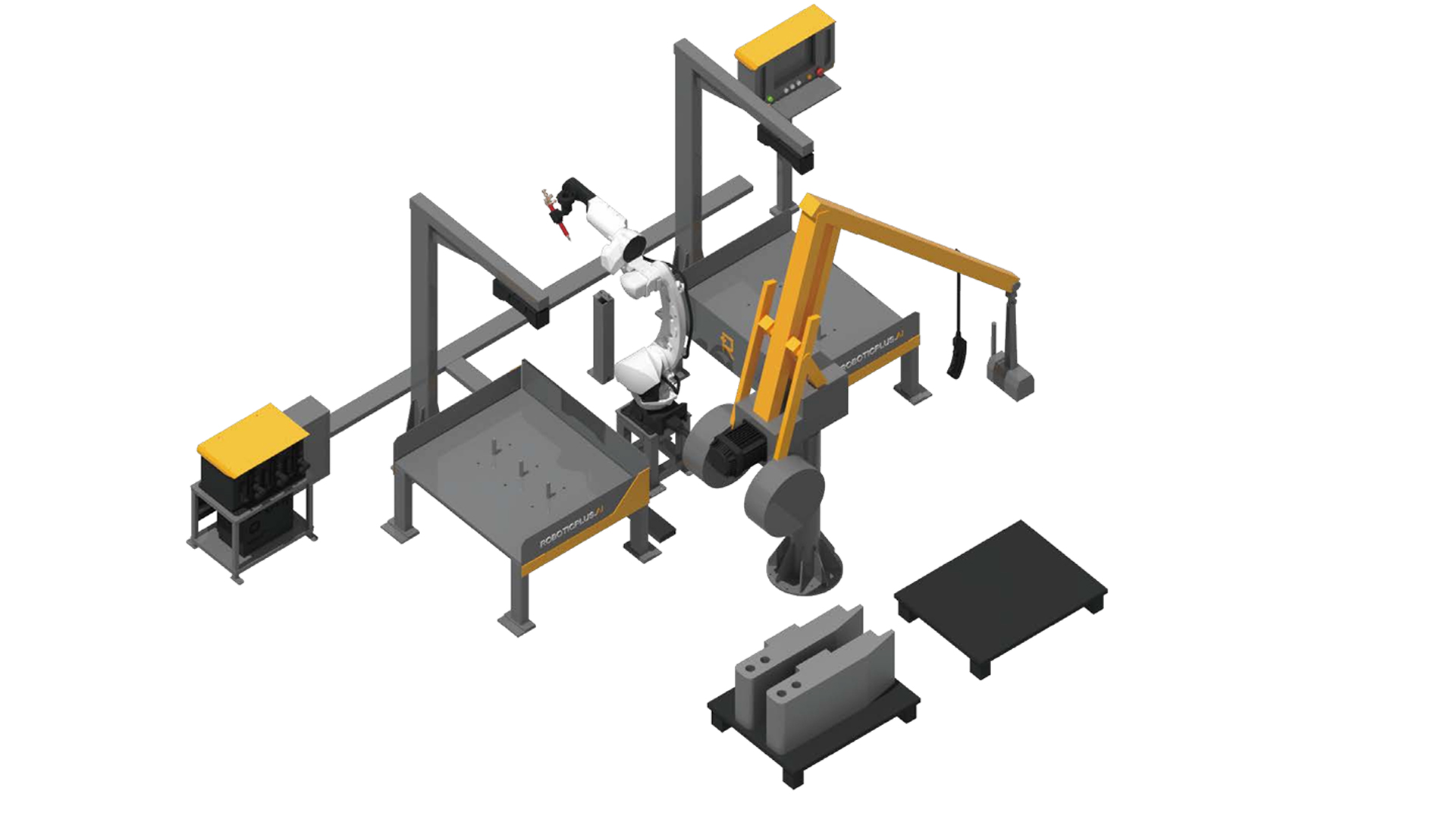

![]() Supports all workpiece sizes with multi-part processing.

Supports all workpiece sizes with multi-part processing.

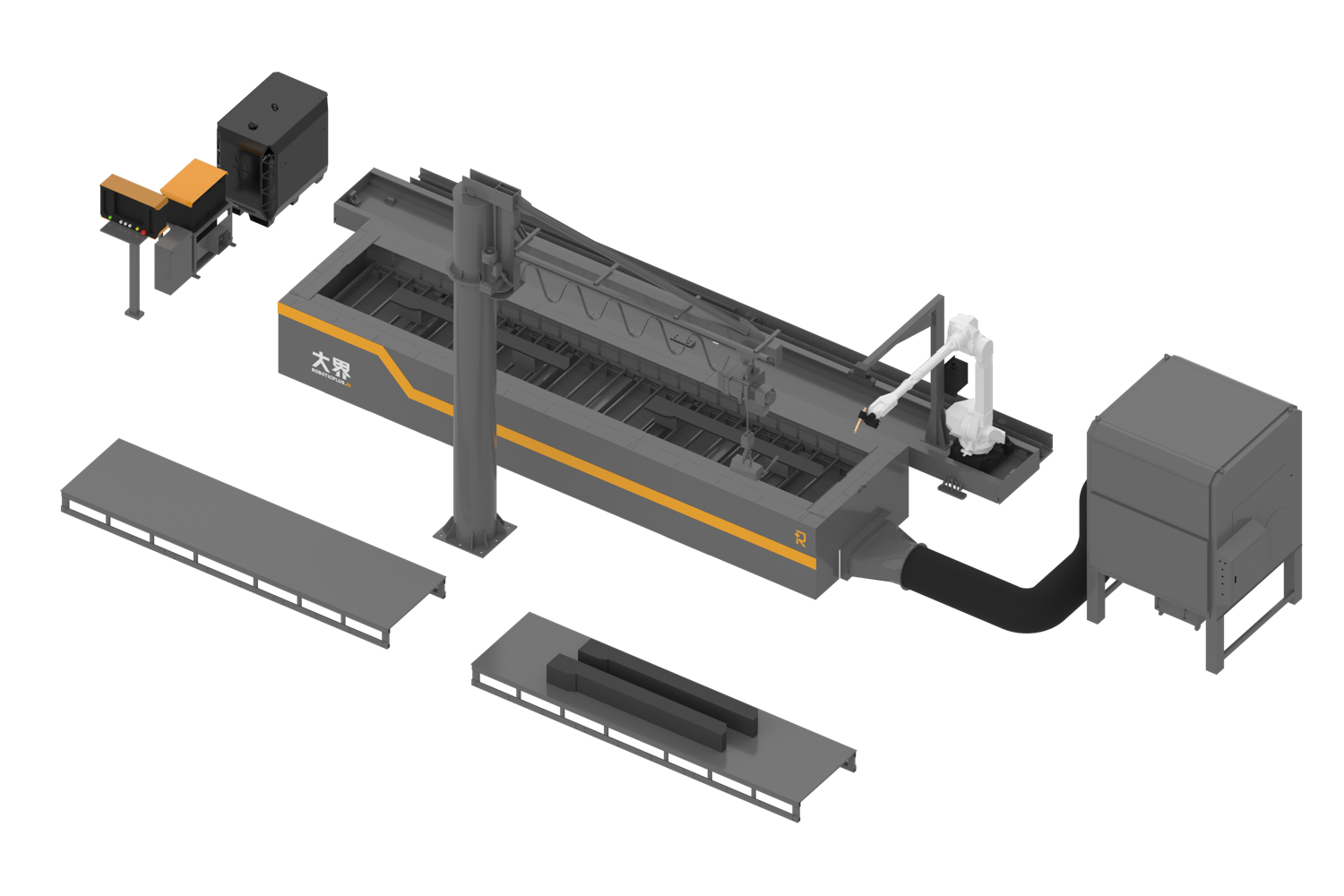

![]() Robot + 7th axis linkage for precise, dynamic bevel cutting of long parts.

Robot + 7th axis linkage for precise, dynamic bevel cutting of long parts.

![]() Line laser scanning for accurate contour detection and size compensation.

Line laser scanning for accurate contour detection and size compensation.

![]() Ultra-fine plasma cutting for fast speed and high precision.

Ultra-fine plasma cutting for fast speed and high precision.

![]() Supports extra-large and multiple workpieces with a wide size range.

Supports extra-large and multiple workpieces with a wide size range.

![]() Fast coarse positioning using multi-line laser with wide field of view.

Fast coarse positioning using multi-line laser with wide field of view.

![]() Accurate contour detection and compensation via line laser scanning.

Accurate contour detection and compensation via line laser scanning.

![]() Robot and gantry move in sync for precise, high-speed bevel cutting.

Robot and gantry move in sync for precise, high-speed bevel cutting.