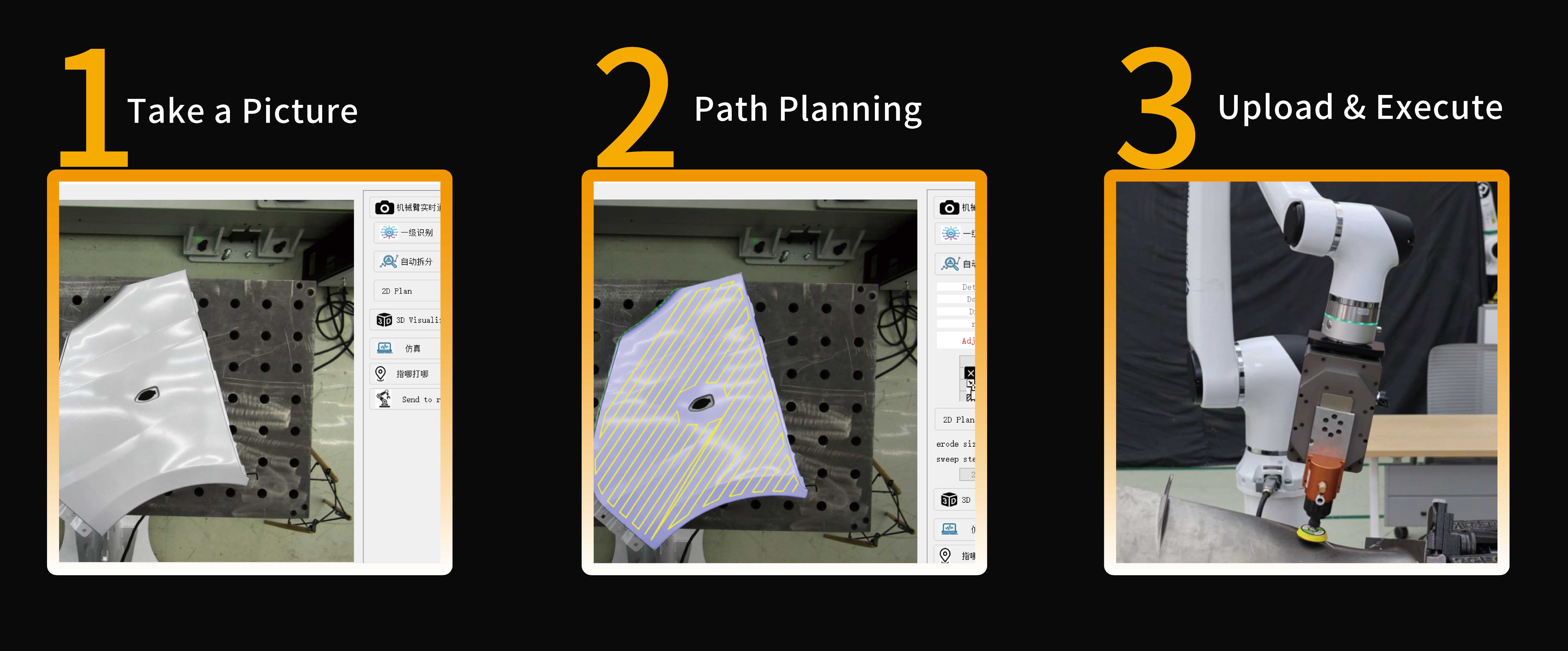

RoboticPlus.AI unveils a next-generation visual interaction control system that integrates AI recognition with intelligent path planning to enable automated grinding—no teaching or modeling required. The system rapidly identifies diverse workpieces, supports photo-based interaction and path simulation, and offers one-click deployment and execution. With no programming knowledge needed, operators can easily manage tasks, significantly boosting the efficiency of flexible manufacturing.

No complex training or skilled labor needed—simple operation completes the grindingprocess in just three steps.

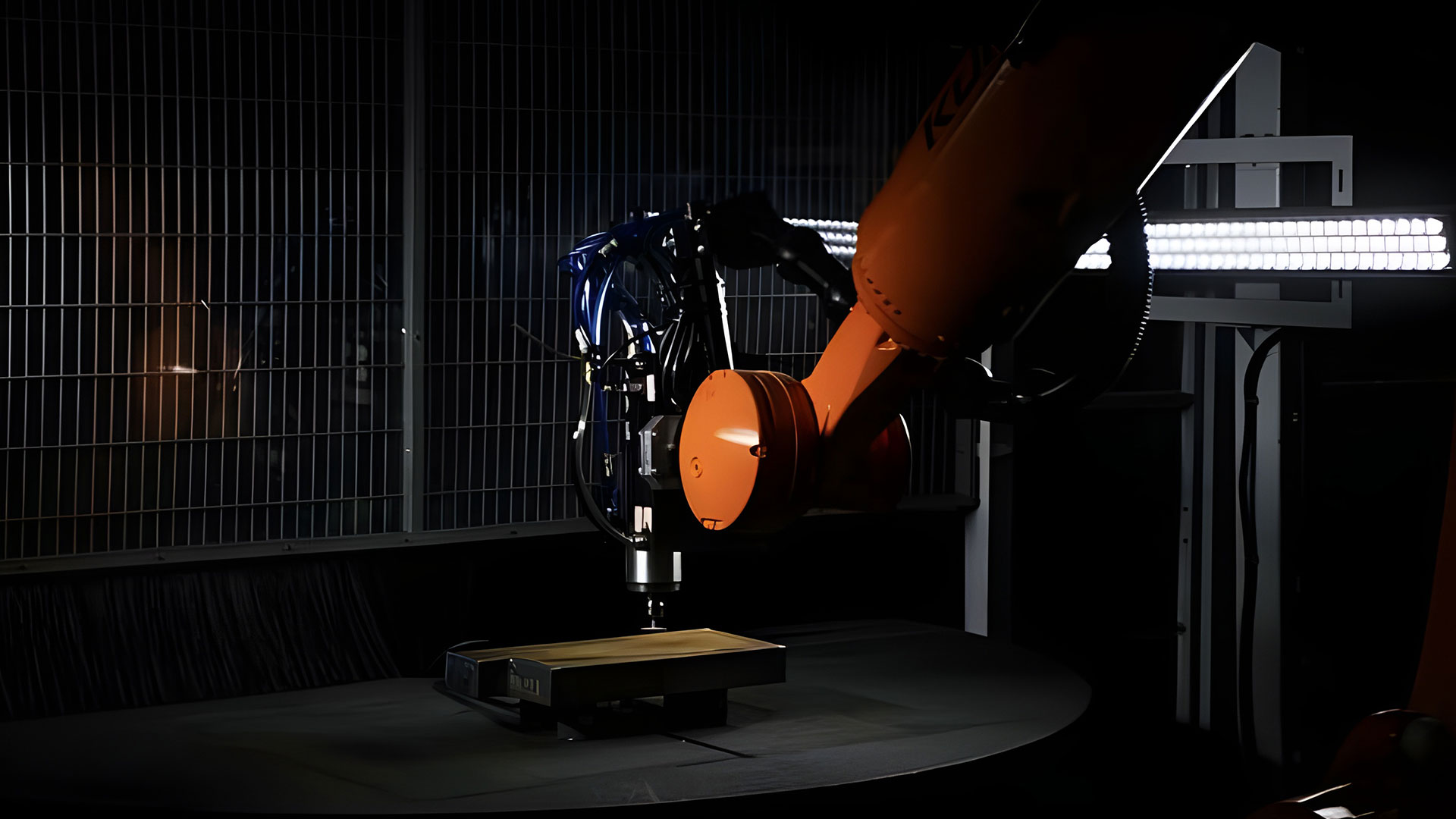

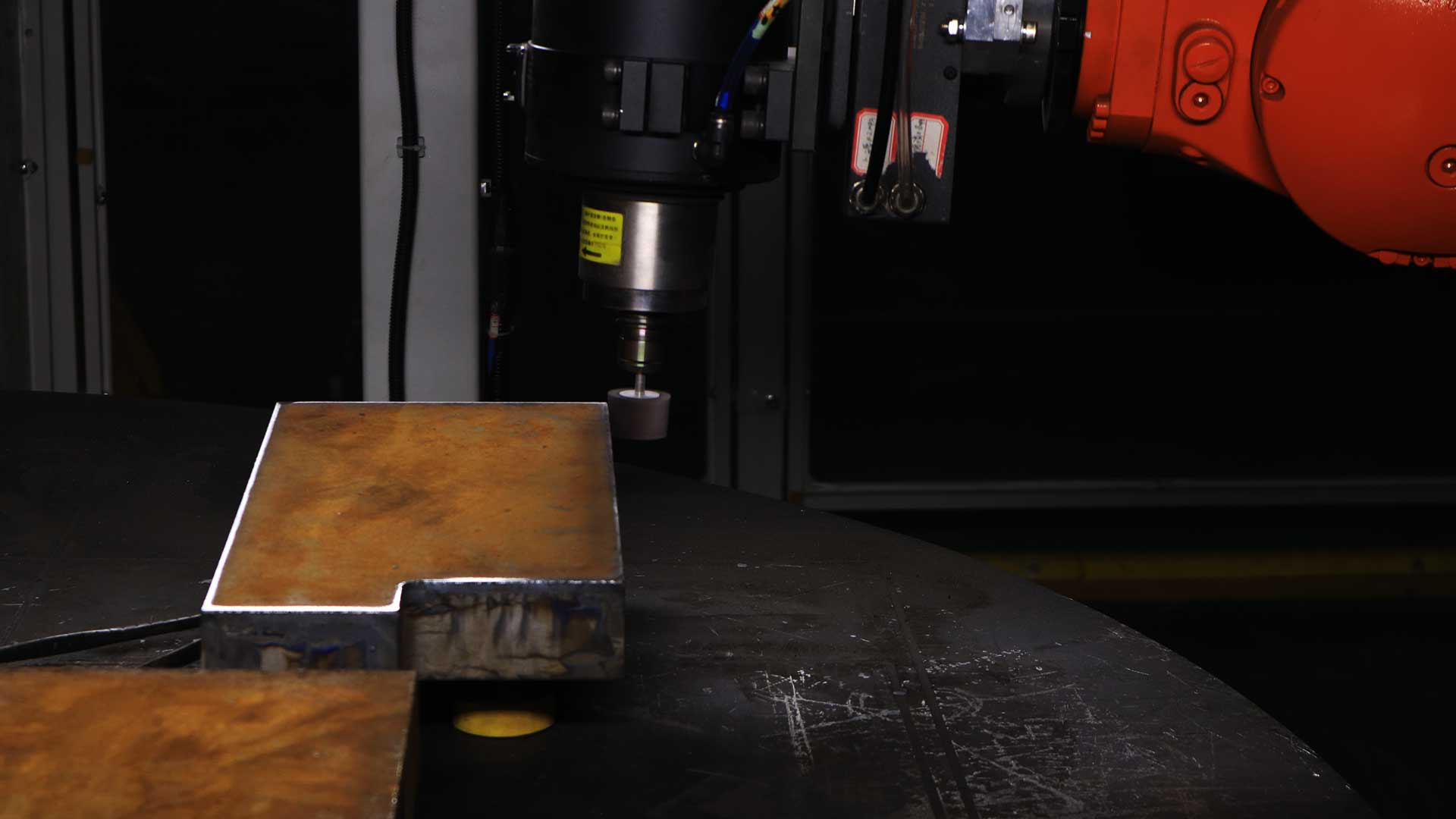

High Efficiency, High Precision

Driven by software and algorithms, it adapts to complex environments for efficient, precise grinding.

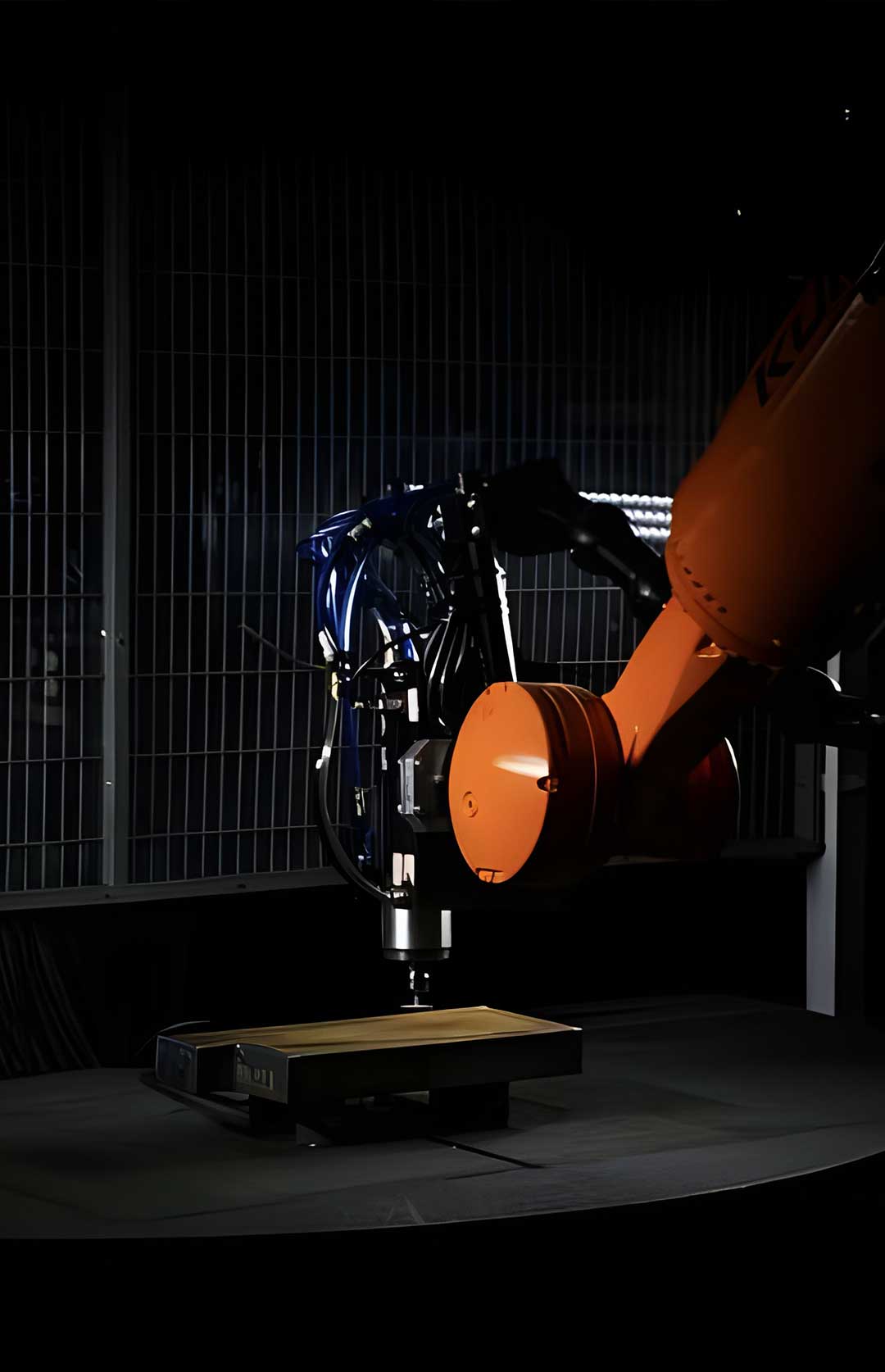

Solve Labor and Safety Challenges

Cut labor reliance and costs, ensure a safer workplace, and overcome recruitment hurdles.

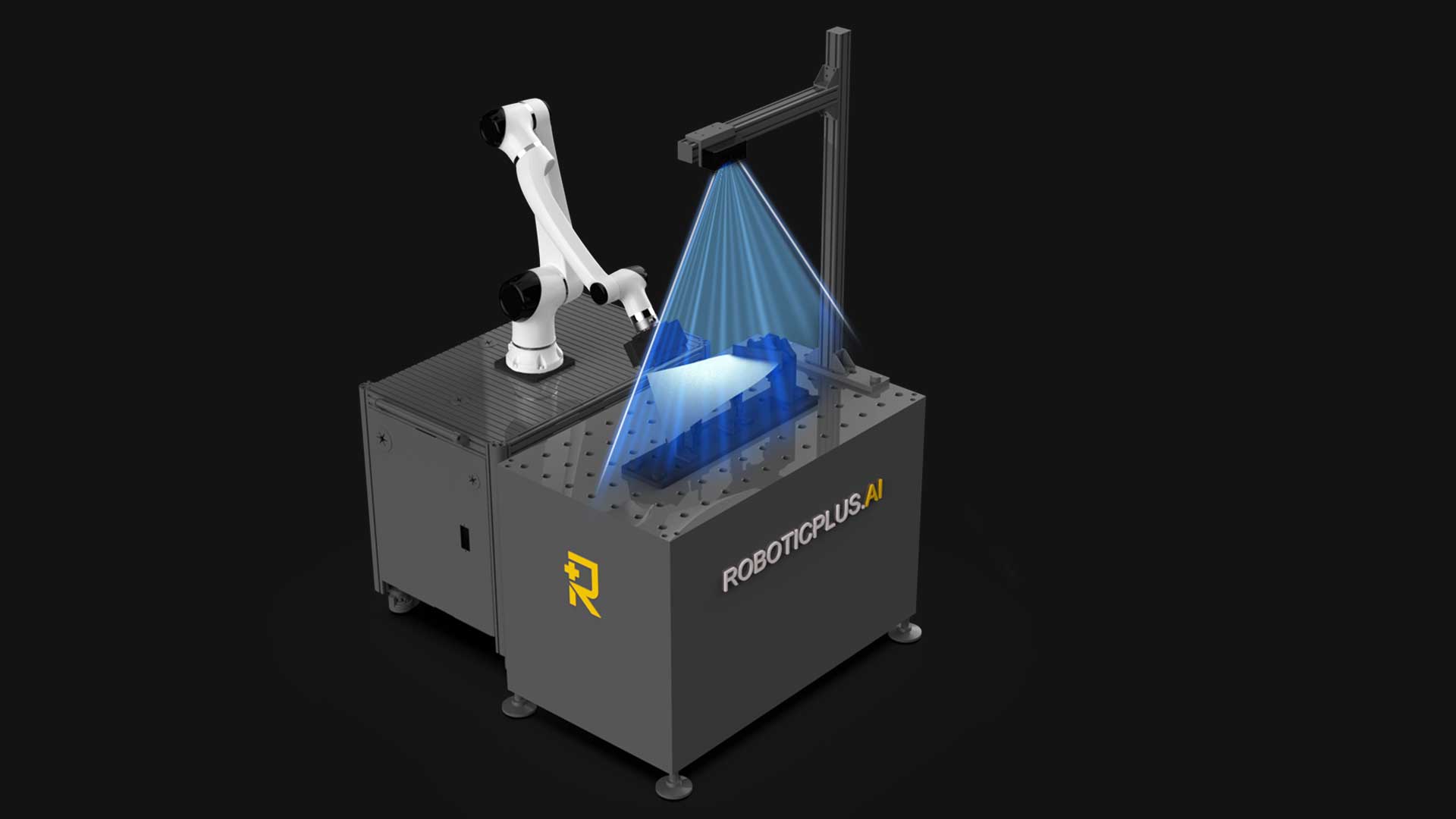

Extremely Flexible for Custom Needs

Flexible adaptation to complex, anisotropic workpieces of varying sizes.

Maximizing Return on Investment

Powered by AI to minimize hardware needs and costs, delivering fast return on investment.

Driven by advanced AI vision technology, RobimGrind effortlessly identifies and adapts to diverse workpieces, making it ideal for small-lot, multi-variety production. Its flexibility ensures consistent quality and efficiency, even in highly customized manufacturing environments.