News

cutting-edge technology

In high-precision sectors like shipbuilding, offshore engineering, and energy, the welding quality of pipe fittings is critical to pipeline system safety. The precision of bevel grinding is especially vital, as it directly determines weld strength.

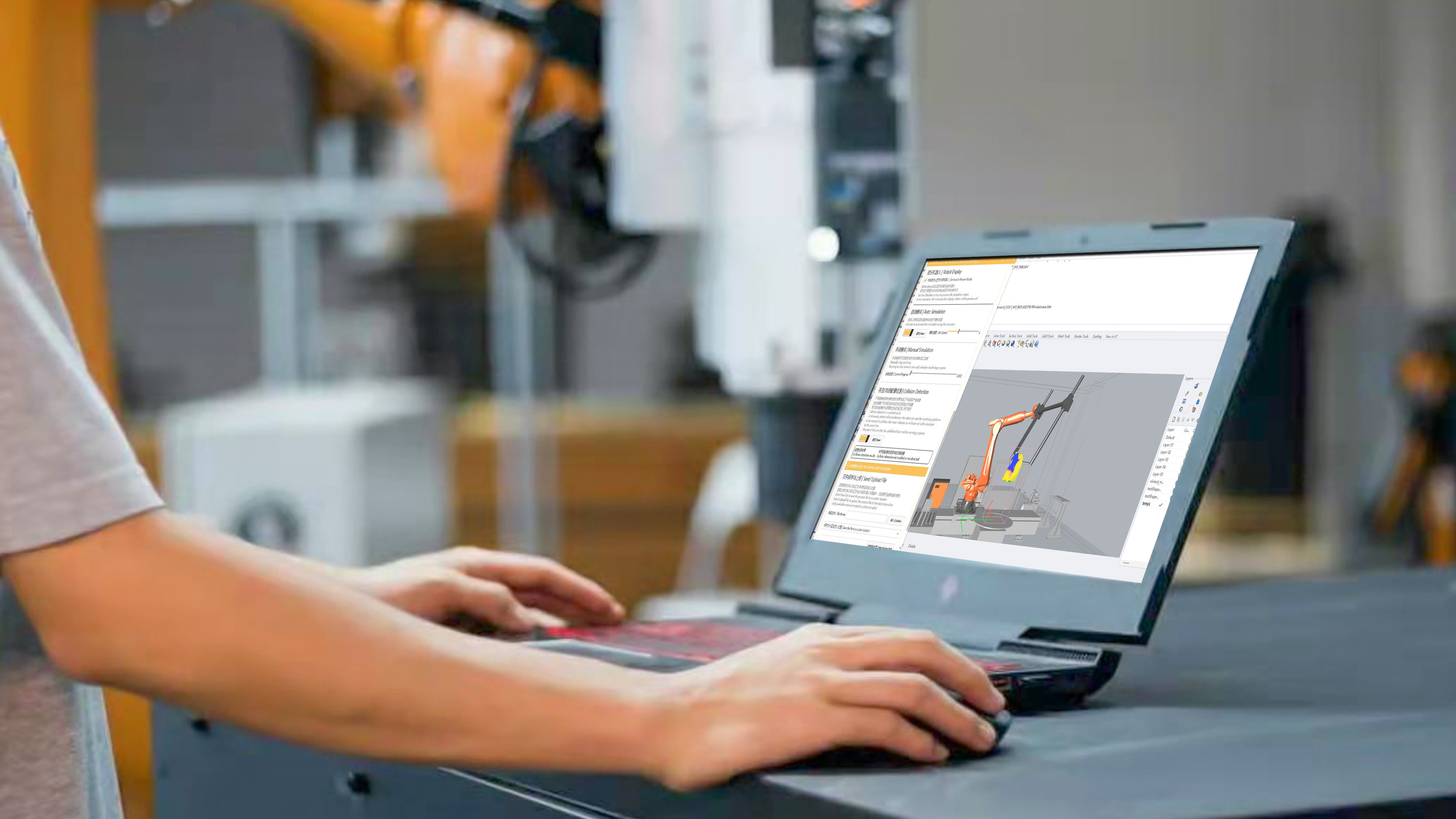

ROBOTICPLUS.AI developed an Intelligent Grinding Center for Pipe Fittings for a leading Chinese offshore equipment company. It precisely grinds internal and external bevels on various components—elbows, tees, reducers, and flanges—delivering superior quality, efficiency, and consistency.

Core Technologies

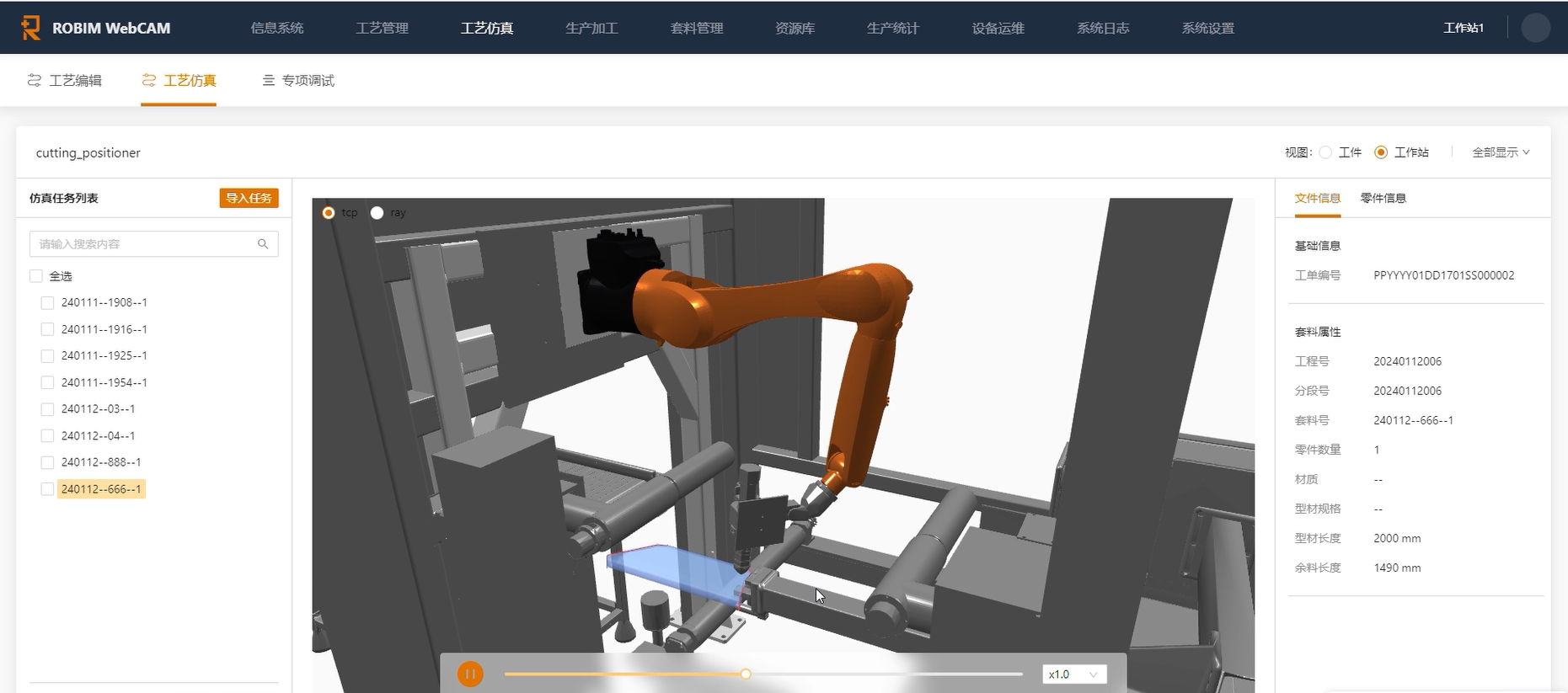

Smart Recognition: Line laser scanning automatically generates high-precision grinding paths with millimeter-level positioning.

Adaptive Force Control: High-precision force-sensing ensures consistent and uniform grinding results.

Smart Tool Management: Real-time monitoring of tool wear and process parameters enables accurate lifespan prediction and automatic material changeover, reducing waste and cost.

Digital Management: Integrated production, process, and quality data modules enable data-driven, intelligent management of the entire workflow.

Key Benefits

Assured Quality: Constant force control and adaptive compensation eliminate critical welding defects, ensuring high consistency.

Doubled Efficiency: Dual-station parallel operation and seamless product switching boost productivity to 2.5 times that of manual work.

Unmatched Versatility: One flexible robotic cell handles multiple pipe types and specifications, reducing the need for dedicated machines and saving on cost and floor space.

People-Centric & Green: A fully enclosed workspace with efficient dust extraction protects workers from hazards, ensuring a safer and more environmentally friendly operation.