News

cutting-edge technology

In collaboration with MECH MIND, RoboticPlus.AI pioneers a cutting-edge 3D bevel cutting solution for construction steel structures, coal machinery, engineering, and ship industries. Leveraging advanced fine positioning techniques based on graphical feature constraints, this innovative system revolutionizes traditional cutting processes.

Current methods for positioning in the steel structure processing industry suffer from inefficiency and imprecision due to thermal deformation and other factors. Traditional approaches, such as manual point-by-point teaching and structured light camera positioning, are unable to meet the demands of flexible production in this industry.

RoboticPlus.AI and MECH MIND, renowned leaders in robotics and AI technology, join forces to address industry pain points. Combining MECH MIND's industrial-grade 3D camera technology with RoboticPlus.AI's expertise in vision algorithms, the partnership introduces a groundbreaking fine positioning method.

MECH MIND's 3D Camera Technology: Offers detailed point cloud data for various objects with high precision and resistance to ambient light, ensuring accurate positioning in complex production environments.

Innovative Vision Algorithm: Developed by RoboticPlus.AI, the algorithm utilizes face array structured light to achieve precise fine positioning of plane workpieces in a single photo, enhancing positioning efficiency.

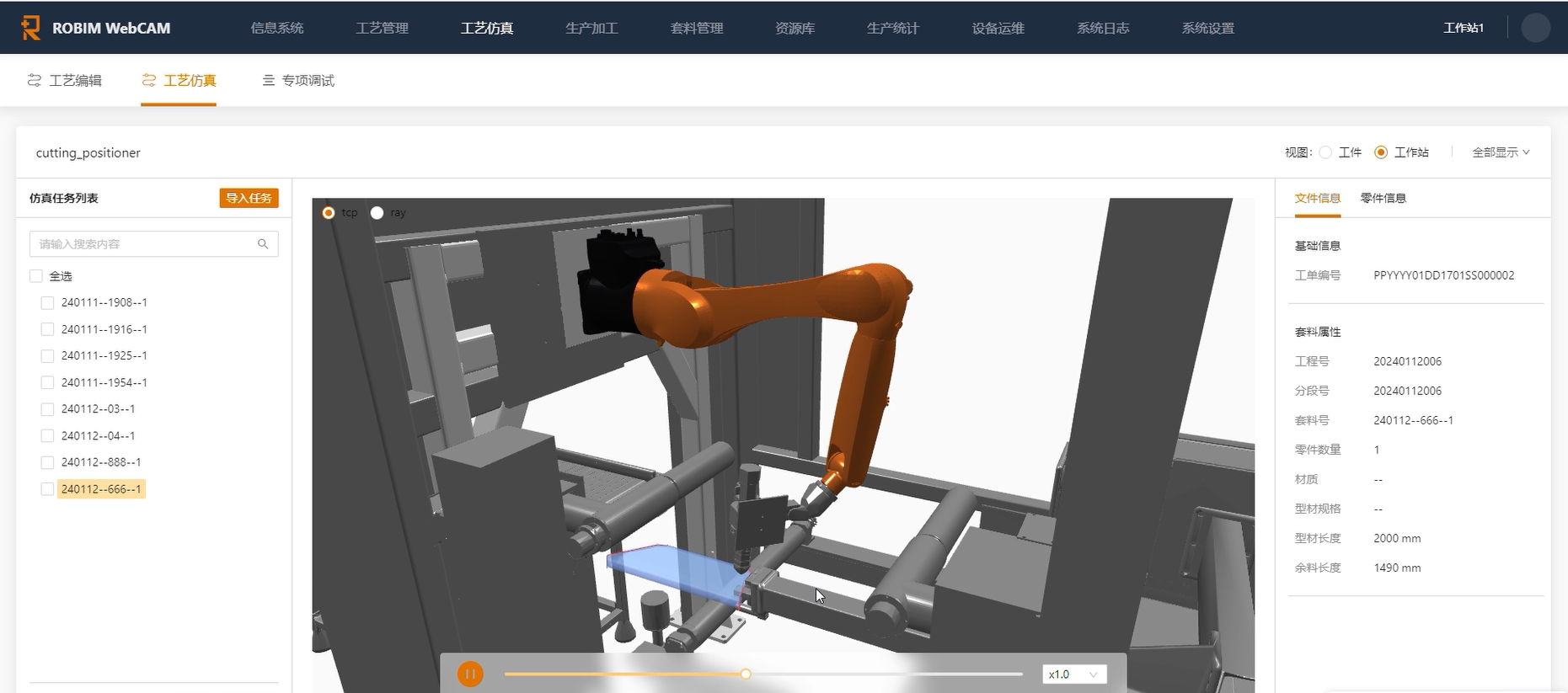

Geometric Algorithm Platform: RoboticPlus.AI's platform reconstructs workpiece contours and generates process paths based on input drawing features, ensuring smooth trajectory planning and collision avoidance.

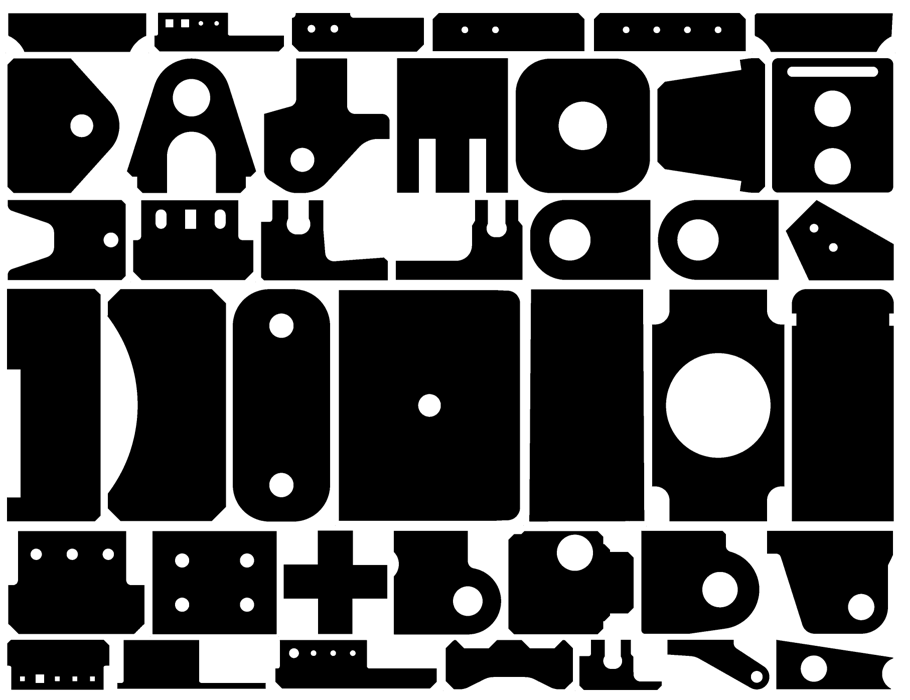

Integrated Methodology: Supports multi-workpiece recognition, various robot brands, cutting processes, and configurations, providing customizable solutions tailored to customer needs.

Enhanced Efficiency: Achieves over 85% utilization rate of cutting robots and more than 75% arc burning rate, significantly improving production efficiency and output.

Precision Cutting: Ensures precise cutting and grinding processes, even in scenarios with short edges, boosting overall quality and accuracy.

Versatile Applications: Adaptable to multiple industries and workpiece types, offering a comprehensive solution for diverse manufacturing needs.

By combining cutting-edge technology with industry expertise, RoboticPlus.AI and MECH MIND set a new standard for bevel cutting solutions, driving innovation and efficiency in the manufacturing sector.

Construction Steel Structure Enterprise, Shanghai:

Small batch production with frequent type changes.

Inefficient manual positioning methods leading to errors.

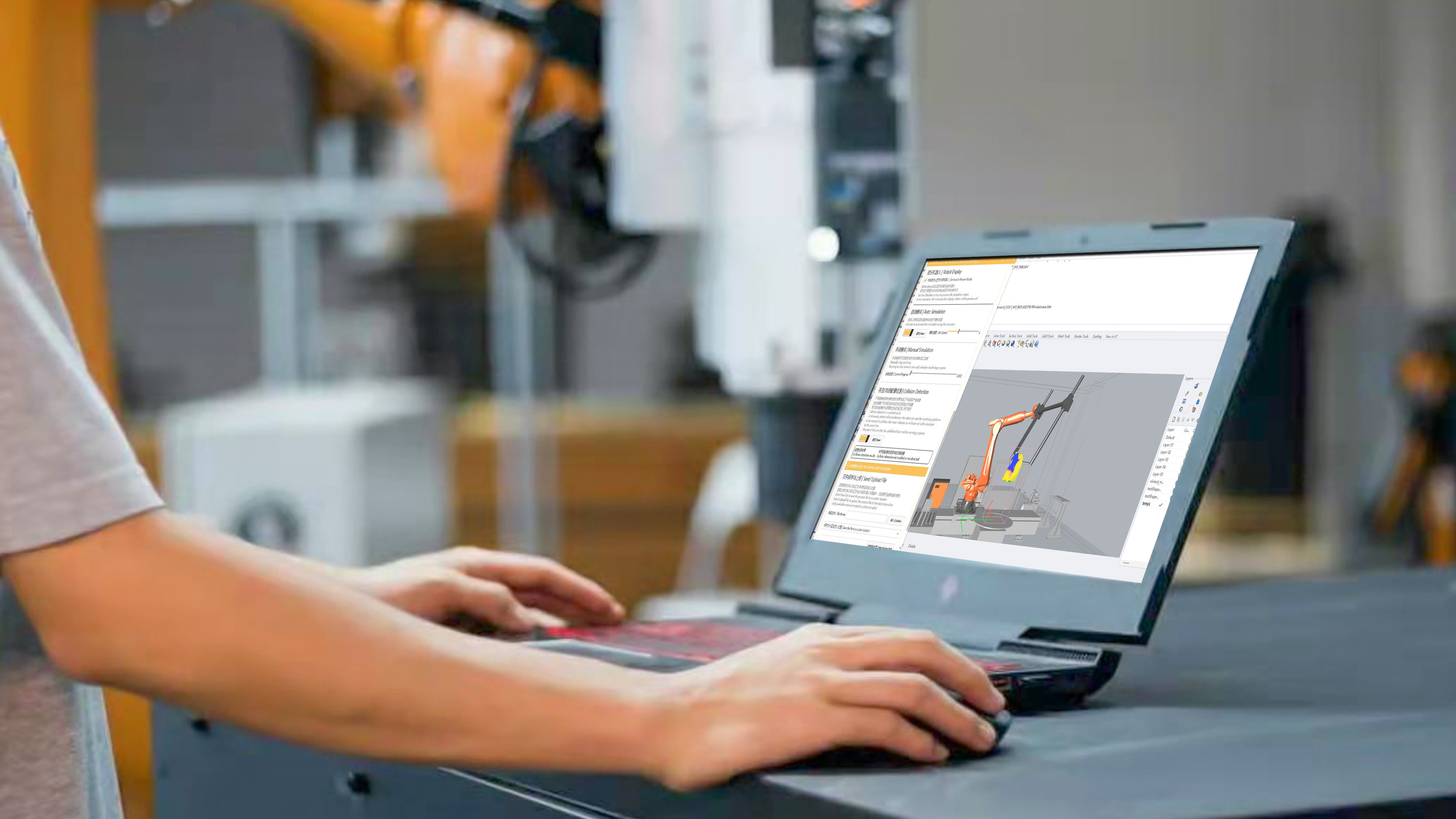

Introduced a dual-station flame cutting robot with integrated visual positioning for flexible production.

Utilized RoBIM software for batch drawing import and automatic parameter setting.

Implemented 3D camera vision algorithm for precise positioning and path planning.

Achieved seamless dual-station connection for continuous 8-hour production, doubling efficiency.

Leading Coal Machine Manufacturer, Henan:

Varied workpiece sizes and types requiring accurate beveling.

Need for adaptable vision systems for complex cutting requirements.

Deployed a fully automatic plasma robot bevel cutting workstation with embedded expert libraries.

Implemented rough and fine integrated visual positioning for efficient, error-free cutting.

Supported data docking and MES system integration for real-time monitoring and scheduling.

Increased cutting efficiency by 2 times compared to traditional methods.

Engineering Machinery Manufacturer, Zhejiang:

Diversified workpiece specifications with high-quality demands.

Cumbersome traditional teaching methods and errors accumulation.

Adopted a standard workstation for dual-station flame cutting, eliminating manual teaching.

Implemented integrated visual positioning for automatic error correction and precise processing.

Utilized RoBIM software for seamless data docking and automatic parameter setting.

Ensured cutting quality and accuracy, enhancing overall production efficiency.