News

cutting-edge technology

Zhengzhou Coal Mining Machinery Group Co., Ltd (ZMJ) stands as the world's premier coal mining technology and equipment supplier. With 28 production, R&D, and sales bases across 18 countries and regions, ZMJ ranks among China's top 100 machinery enterprises and Fortune China's top 500.

As pioneers in coal machinery, ZMJ drives China's high-end hydraulic support technology independently. They achieved the world's first successful industrial application of hydraulic support for large mining heights exceeding 6 meters, replacing imported models. Recently, they unveiled the world's first intelligent hydraulic support for large mining heights of up to 10 meters, cementing their global leadership.

Behind ZMJ's record-breaking feats lies their cutting-edge factory, symbolizing the pinnacle of intelligent manufacturing in coal machinery. To further advance industry leadership, ZMJ partners with RoboticPlus.AI to boost innovative investment in high-end equipment manufacturing.

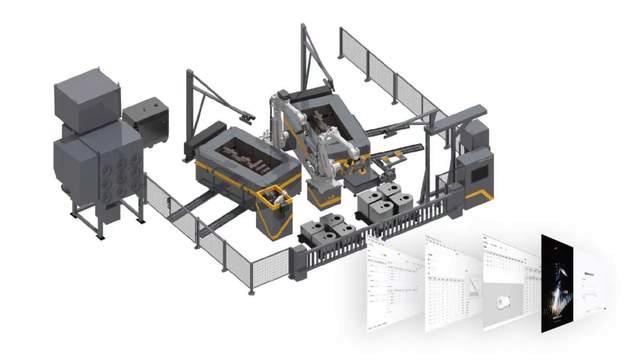

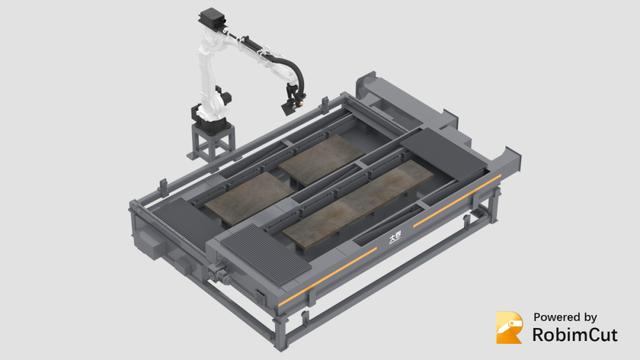

RobimCut Facilitates Flexible Production of High-End Hydraulic Brackets

The production of hydraulic brackets involves numerous parts with varied specifications, posing challenges for traditional methods. Current industry issues include:

1, Labor-intensive robot teaching, inefficient for flexible production, leading to increased costs.

2, Inconsistent workpiece contours requiring adaptive cutting methods.

3, Labor-intensive grinding processes occupying valuable space.

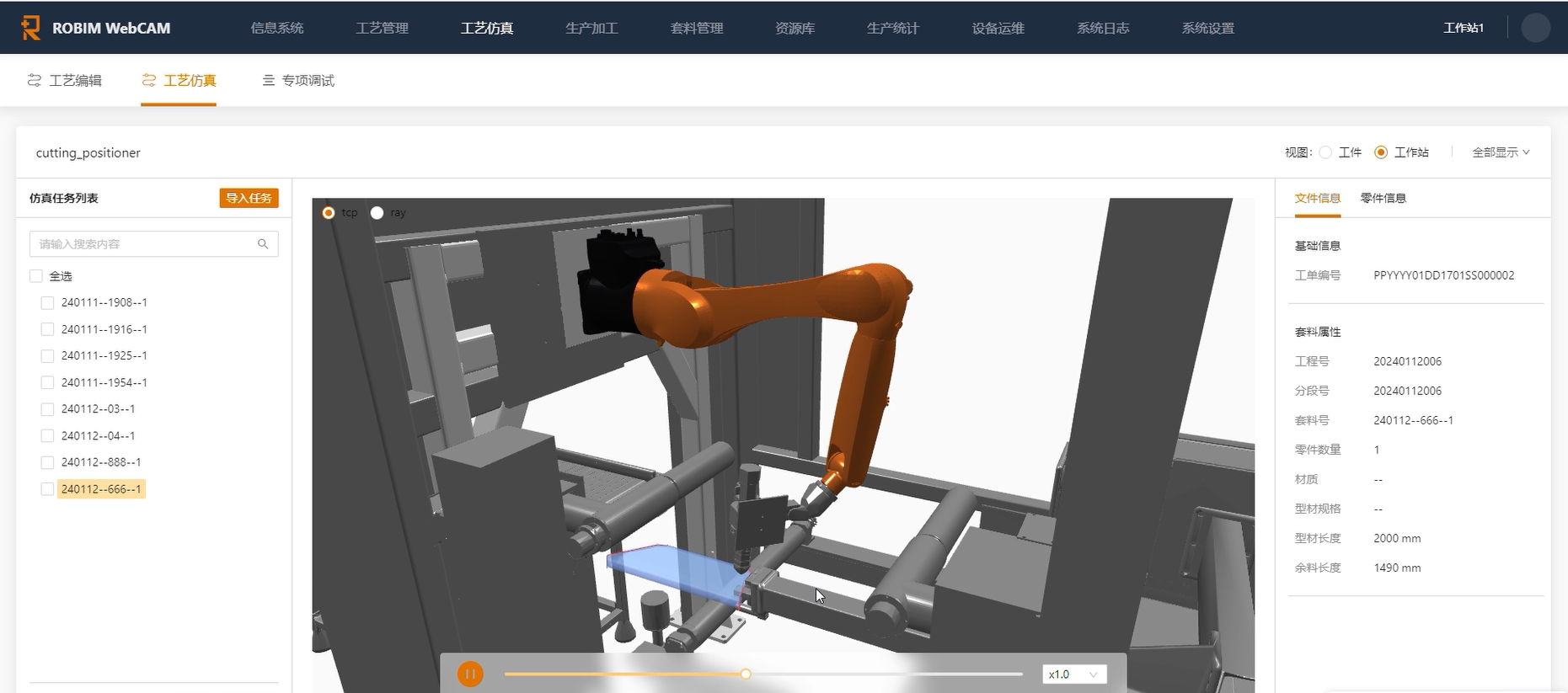

We offer the RobimCut intelligent bevel cutting solution to Zheng Coal Machinery. Leveraging our proprietary software and algorithms, we address issues such as workpiece deviation, tooling location difficulties, and manual teaching inefficiencies. Our solution enables seamless adaptation to on-demand customization, facilitating fully automatic production processes including loading, cutting, sanding, and unloading."

Advantages:

1, RobimCut's intelligent software ensures simplicity and efficiency. It automatically configures cutting parameters and generates machining programs, eliminating the need for programming. With a user-friendly interface, it offers stability and ease of use.

2,Utilizing advanced geometric AI algorithms, RobimCut enables direct design data docking and automatic matching of process paths. It streamlines the identification of bevel geometry information and selects optimal cutting paths from the BevelMaster library, enhancing efficiency.

3. RobimCut offers dual vision positioning modes for flexible cutting of large and small workpieces. The integrated one-time fine vision positioning function allows accurate cutting of small parts in seconds, while the laser line scanning function facilitates efficient cutting of large parts.

4,RobimCut provides autonomous grinding capabilities, enhancing material flow efficiency by performing direct grinding without tool head switching. This streamlined process eliminates the need for manual secondary cleaning and grinding, significantly improving workshop efficiency.

5,RobimCut enables real-time collection, monitoring, and visualization of production data. It integrates with Zheng Coal Machinery's MES system for real-time equipment data monitoring, energy consumption tracking, and seamless production scheduling and task reporting, ensuring efficient workflow management.

Building Industry Excellence Through Trusted Partnerships

As a leader in high-end hydraulic support, Zheng Coal Machinery sets the standard for production processes and manufacturing. With top market share and robust production capacity, they demand equipment stability, production accuracy, and automation for uninterrupted 24-hour production.

Our RobimCut intelligent bevel cutting program exceeded expectations, meeting Zheng Coal Machinery's high standards. Compared to traditional methods, our program boosts production efficiency by 30% and triples output. It accommodates 95% of part specifications, alleviating production bottlenecks and demonstrating industry leadership.

Given our proven technical prowess and results, we've embarked on second and third-phase cooperation. Multiple beveling workstations undergo intelligent transformation, solidifying Zheng Coal Machinery's position and elevating industry standards, enhancing national brands.